AUTOMOTIVE EXPERIENCE AND ENGINEERING KNOW-HOW

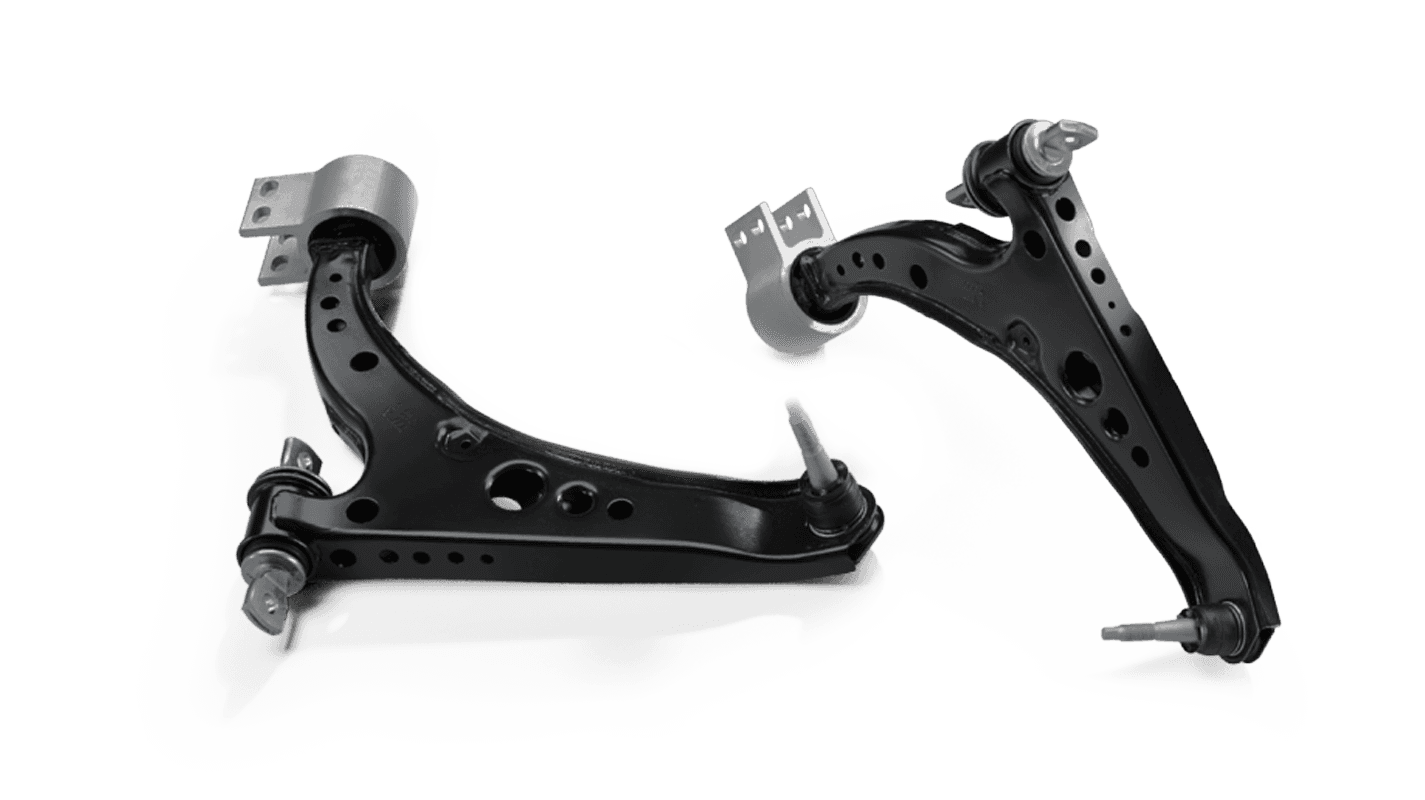

GEDIA develops automotive lightweight construction technologies and chassis components for the automotive industry, to get people to their destination safely and energy-efficiently in the cars of the future.

GEDIA is constantly researching new solutions to bring high quality body components and reliable, functional crash safety elements to the road. Essential to GEDIA's success is its experience in combining different materials, forming techniques, and joining technologies.

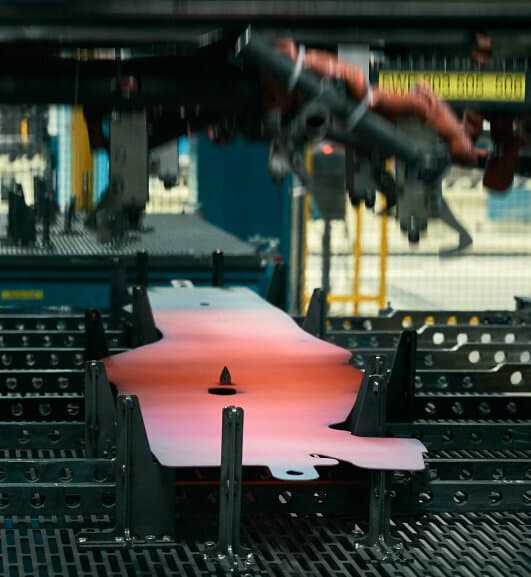

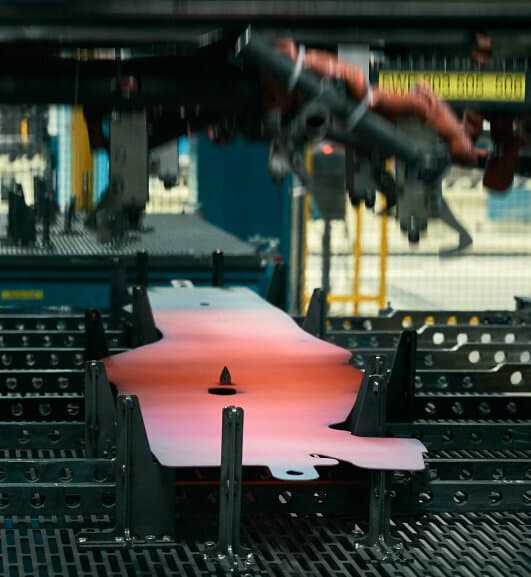

REACHING NEW FRONTIERS WITH HIGH-TECH FORMING TECHNOLOGY

Close cooperation between the various trades helps to ensure that production processes can always run efficiently, i.e. with maximum material utilization and minimum energy consumption. Component development, in-house prototype production, and toolmaking work hand in hand. In order to make mobility future-proof and sustainable, GEDIA cooperates with science and research and invests in Industry 4.0.

THE RIGHT MATERIAL, IN THE RIGHT PLACE, IN THE RIGHT QUANTITY

For individual customer requirements

With the highest level of expertise, engineers and technicians develop innovative solutions and research new technologies to meet individual customer requirements.

Innovative interplay of material, technology and design

GEDIA is concerned with innovative material compositions, intelligent joining technologies and new component designs and is actively involved in the development of lightweight construction in the automotive industry.

Everything from a single source - the results of product and process development are validated in our own prototyping department. Here, initial component production experience and insights into component design are acquired. The results are near-series test parts that are used for our own tests. Thanks to the latest 3D printing technology, we are also able to make electronic models “tangible” quickly and cost-effectively.

Excellent! Our toolmaking department is one of the best toolmaking companies in Germany. For the third time, GEDIA has been honored in the "Excellence in Production" competition. As the overall winner in the category "internal toolmaking with over 50 employees", the in-house toolmaking department prevailed against tough competition from over 300 participating companies.

Everything from a single source - More than 160 employees in Germany and China design, machine and assemble tools and fixtures according to the latest standards. The toolmaking department is supported by the company’s own prototype activities. Findings from product development are thus consistently used in tool design. A network of international tool manufacturers complements the company's own capacities.

Secure through standardization – State-of-the-art production and standardized production facilities offer extensive capacities and make GEDIA so efficient.

Top tier service from a competent and capable team

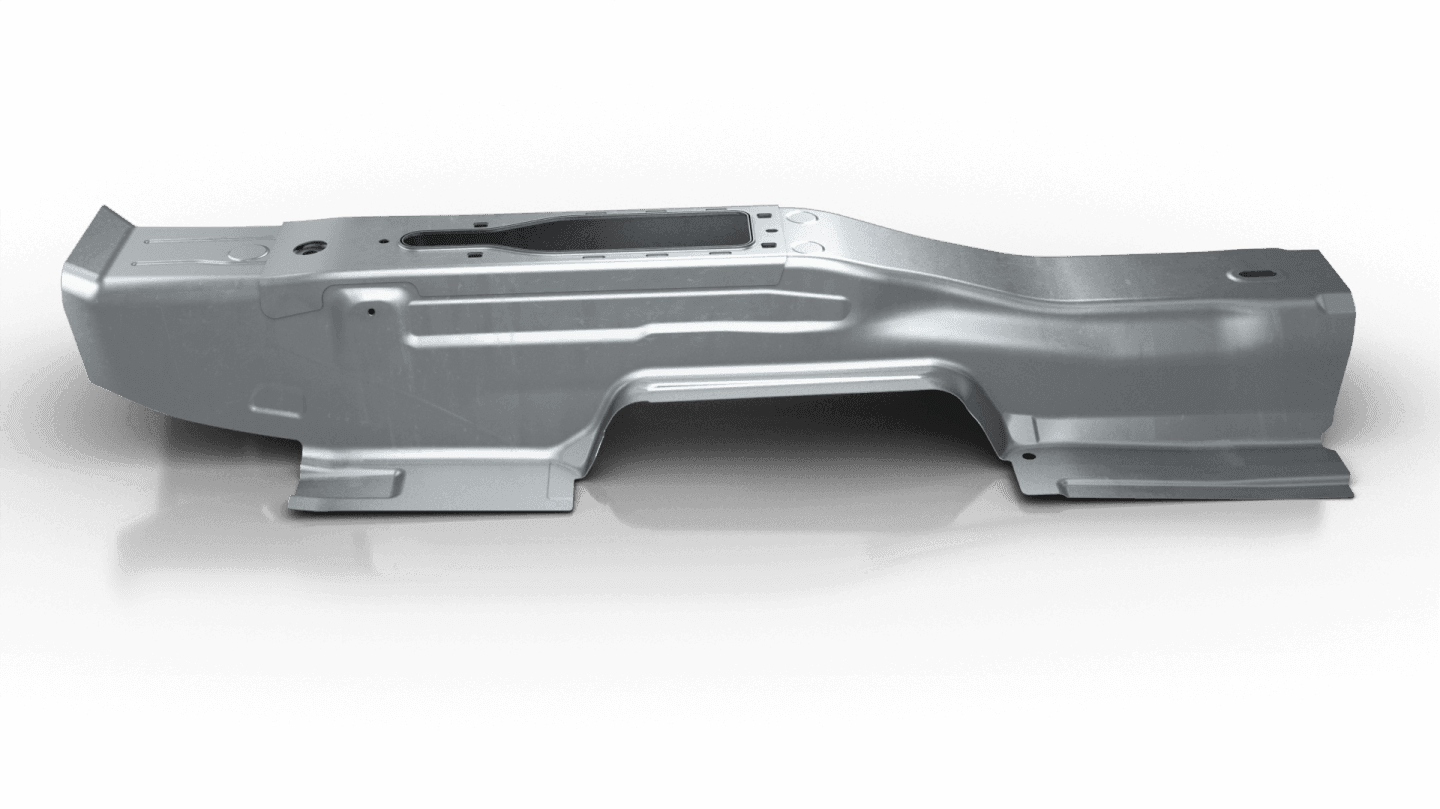

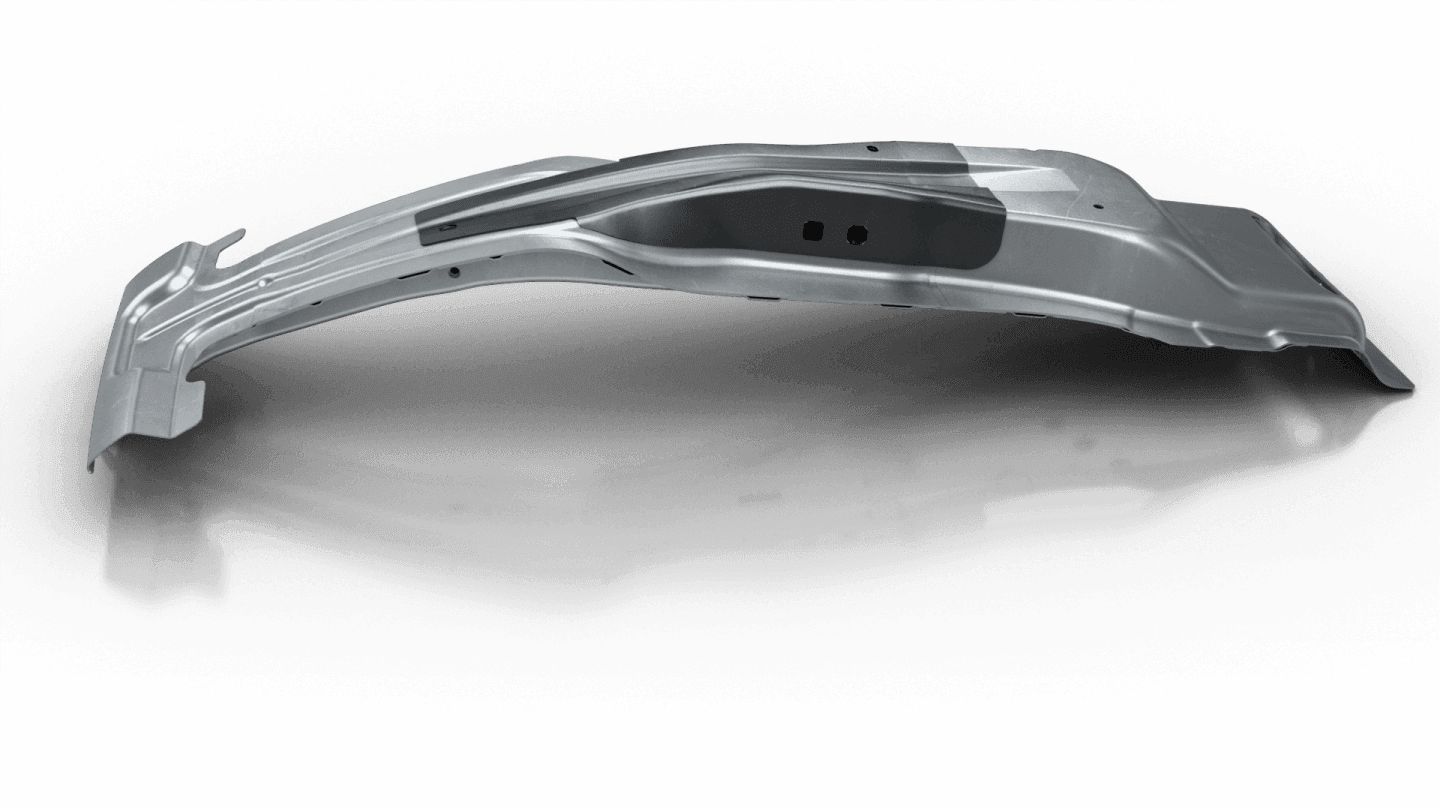

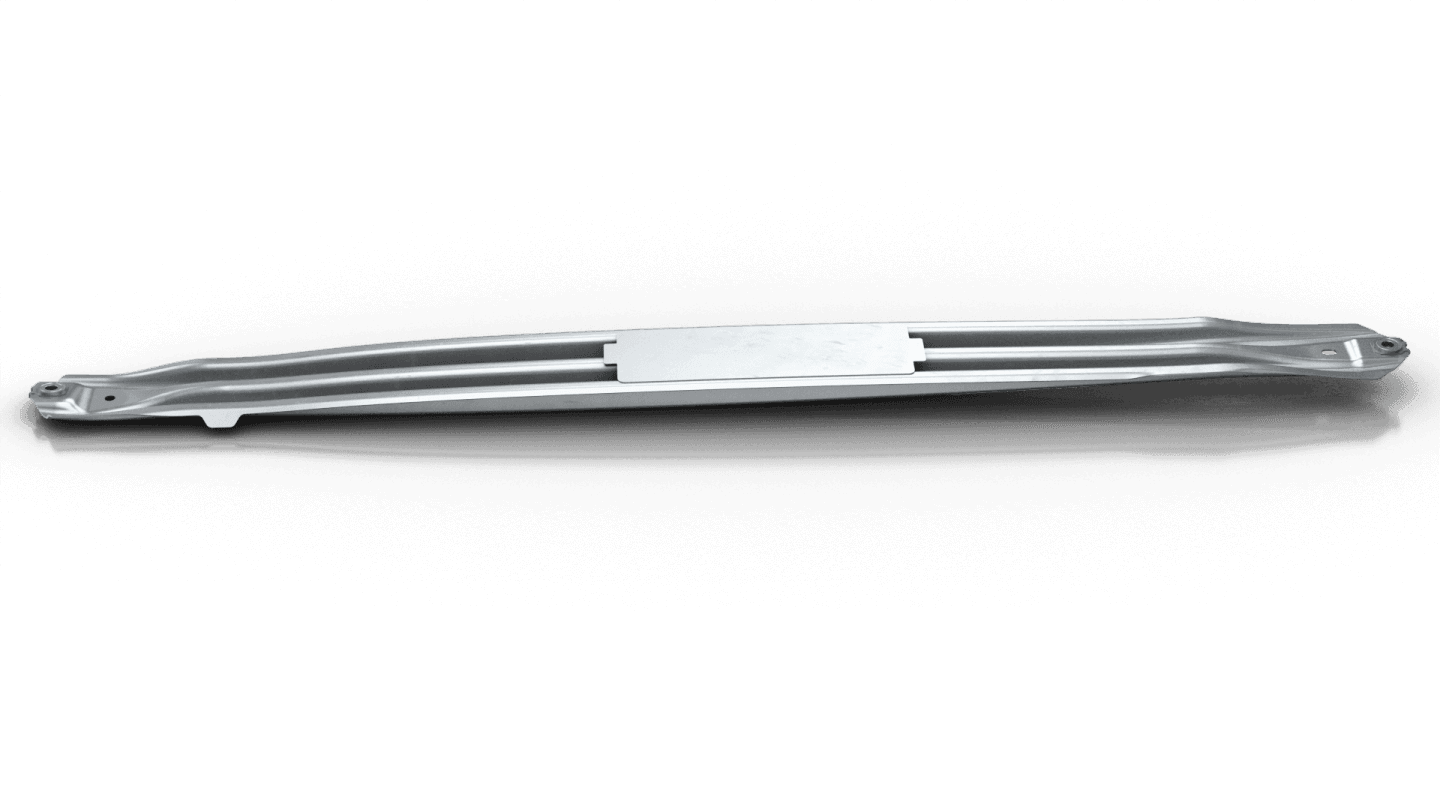

GEDIA develops and produces structural parts and assemblies for automotive lightweight body construction as well as chassis components. The use of cold and hot forming as well as state-of-the-art joining technologies make it possible to manufacture lightweight body components at the very highest level.

Selected components and assemblies from GEDIA: