The front frame extension connects the underbody structure to the bumper. The precisely matched material qualities used for each individual part guarantee controlled deformation in the event of a crash.

Manufacturing Processes:

- Cold Forming

- Projection Welding

- Resistance Spot Welding

- MAG Welding

- Painting

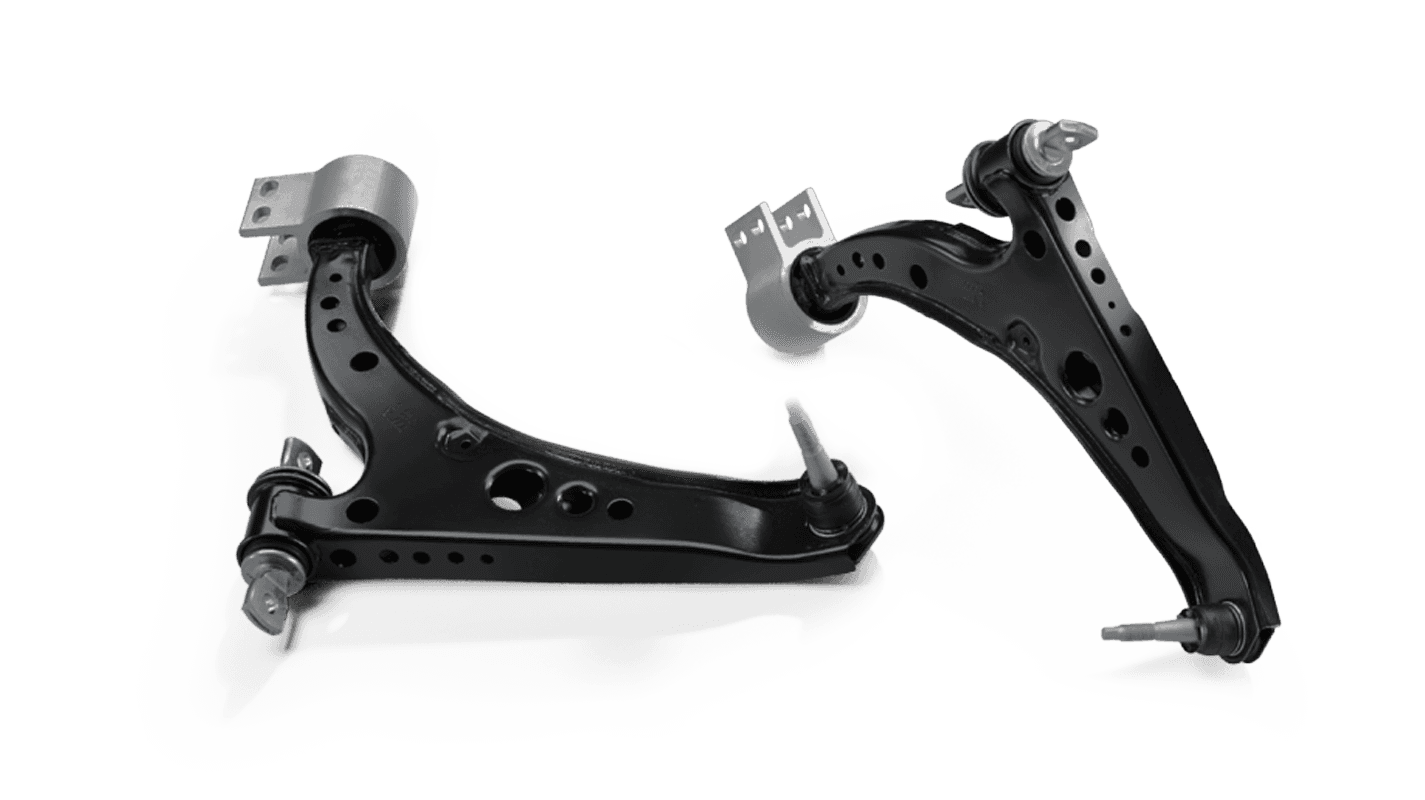

The side impact beams sit horizontally in the doors and serve to reinforce the doors in the event of a side impact. Working with the B-pillar and other reinforcements, they help maintain the integrity of the passenger compartment in the event of an accident.

Manufacturing Processes:

- Cold Forming

- Laser Welding

- Painting

- Final Assembly

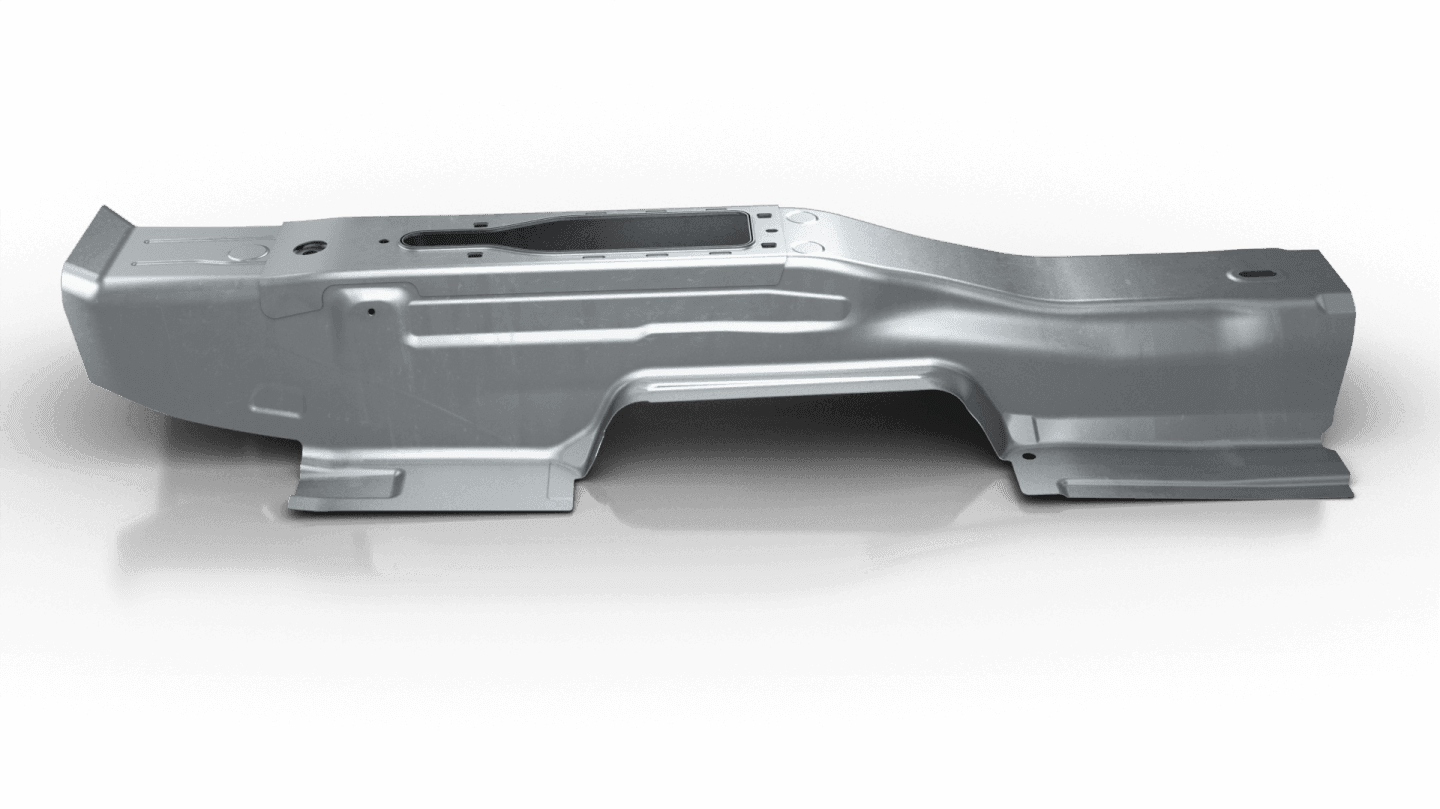

The crash box absorbs energy in the event of a rear impact and has a reinforcing function when the towing eyes are used. A laser-welded plate is used to meet load requirements.

Manufacturing Processes:

- TWB Material

- Cold Forming

- Projection Welding

- Resistance Spot Welding

Bumpers play a central role in the safety of cars and trucks. At GEDIA, we prioritize the use of reliable, high-quality materials in the production of safety-critical welded assemblies. Our products utilize advanced materials, including high-strength and ultra-high strength steels, along with precision-engineered add-on components. Whether mounted at the front or rear of the vehicle, every bumper from GEDIA plays a vital role in enhancing both active and passive vehicle safety.

Manufacturing processes:

- Cold Forming

- Hot Forming

- Projection Welding

- MAG Welding

- Resistance Spot Welding

- Painting

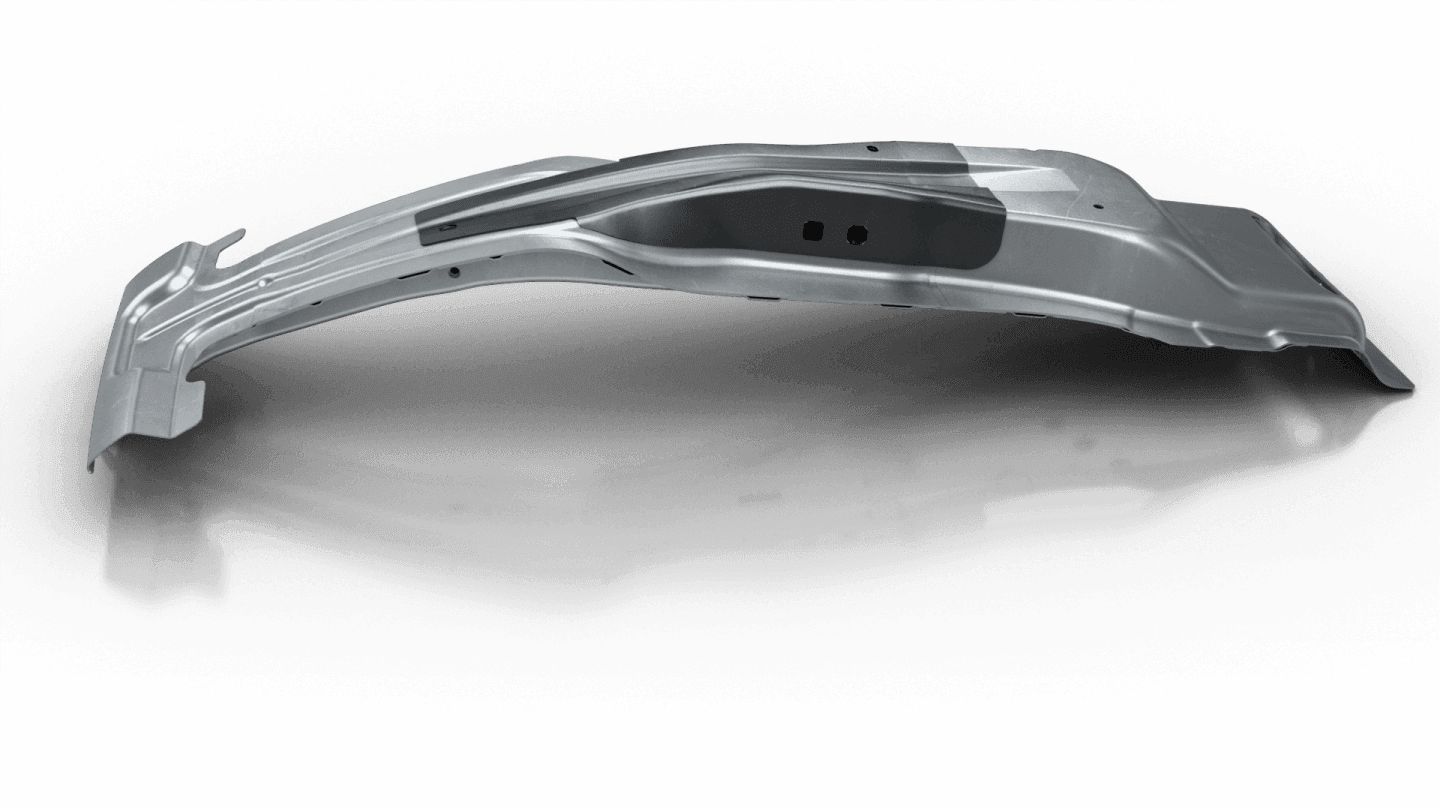

Bumpers play a central role in the safety of cars and trucks. The GEDIA commercial truck bumper is a safety-critical component located under the outer paneling of the driver's cab. Bolted to the chassis directly below the headlights, it offers two attachment points for towing eyes. The bumper is constructed using high-strength and ultra-high strength steels, along with coordinated attachment components.

Manufacturing Processes:

- Cold Forming

- Hot Forming

- 3D Laser Cutting

- MAG Welding

- Painting