The intermediate tunnel level is located in the vehicle floor and fulfills several structural and functional tasks. Among other things, in electric vehicles it protects the battery from external influences such as impact forces or road damage.

Manufacturing Processes:

- Punching

- Riveting

- Welding

The battery tray and lid provides safe and robust protection for the high-voltage battery of electric vehicles. It is seamlessly integrated into the vehicle, ensures structural stability and protects the battery from external impacts such as shocks or environmental influences.

Manufacturing Processes:

- Punching

- Hot stamping plus laser welding

- Automated spot welding and additional application of sealants

- Leak test

- Electro-dip coating

The tunnel is located below the occupant cabin and is used to accommodate driveline components, the gear lever unit, and the center console. On the inside, the tunnel supports the center console and associated components. On the outside, the tunnel panel covers the exhaust and/or driveline components for rear-wheel drive vehicles. The tunnel can be considered the central channel of the vehicle.

Manufacturing Processes:

- Blank Stamping

- Hot Forming

- Laser Cutting

- Resistance Spot Welding / Projection Welding

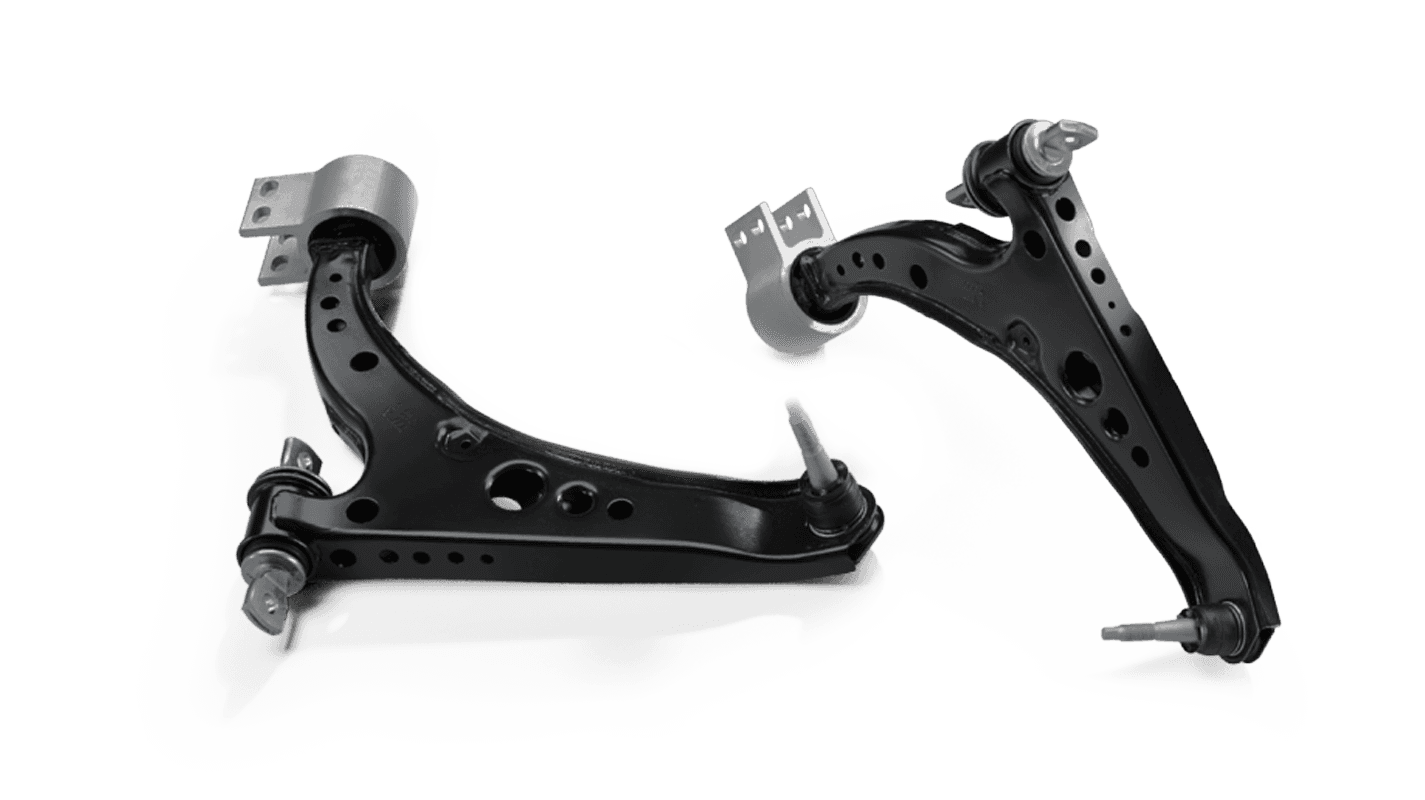

The front and rear rail assemblies, the longitudinal members, serve as the load-bearing components of each floor assembly. In addition to performing different mounting functions for the floor assembly and chassis, the longitudinal members have a significant influence on the rigidity and crash safety of a vehicle body.

Manufacturing Processes:

- Tailor Welded Blank (TWB) Material

- Deep Drawing

- Thread Forming

- Projection Welding

- Resistance Spot Welding

- MIG Welding

- Adhesive Application

- Stud Welding

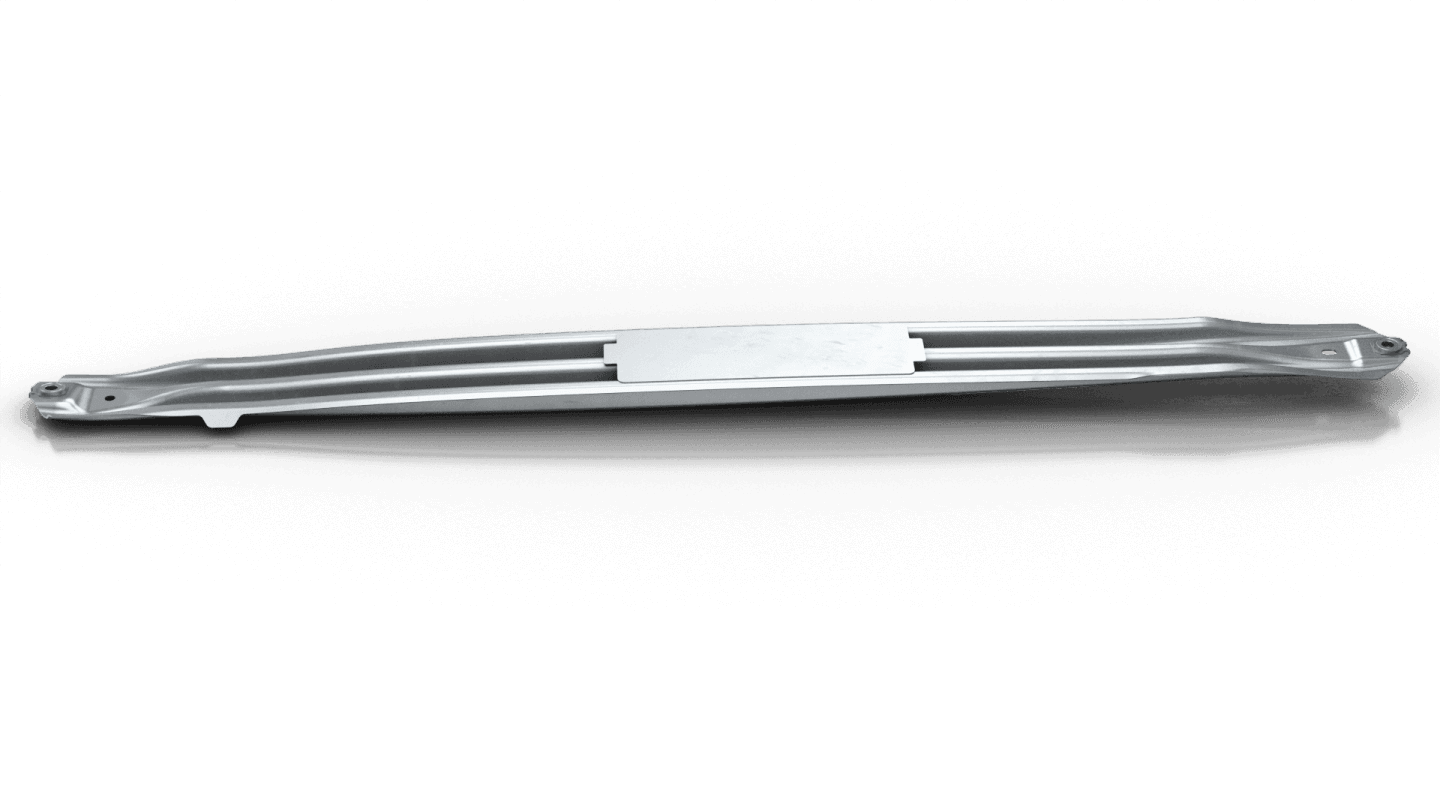

The side skirts are a safety-relevant element of the body. In order to introduce the impact energy into the body structure in a targeted manner, the strength must be precisely defined. GEDIA manufactures sill reinforcements from welded blanks or tailored-rolled blanks.

Manufacturing Processes:

- Forming (punching)

- Glue

- Spot welding

Assembled from many different components, the lower partition wall forms the end of the floor assembly at the front and separates the vehicle interior from the engine compartment.

Manufacturing Processes:

- Cold Forming

- Resistance Spot Welding

- Adhesive Application

The aluminium thrust field is used to increase the rigidity of the body. It is an attachment point between the front axle and the steering to ensure the load capacity of the car.

Manufacturing Processes:

- Circumcise

- Pull

- Punch

The seat crossmember is used to accommodate the front seats of the vehicle and as part of the life module to protect the occupants, especially in the event of a side impact. It consists of two aluminium extrusion profiles, three aluminium sheet metal components, eight threaded threads, 70 self-pierce rivets, ten metres of laser seam and one metre of adhesive seam.

Manufacturing Processes:

- Deep drawing and bending

- Tapping

- Self-pierce rivets

- Glue

- Laser welding

- Bolt Setting

- Lacquer

The axle connection bracket connects the front end of a vehicle with the center of the floor. This bracket serves as reinforcement for the longitudinal members.

Manufacturing Processes:

- Blank Stamping

- Cold Forming

- Thread Forming

- Resistance Spot Welding

- MIG Welding

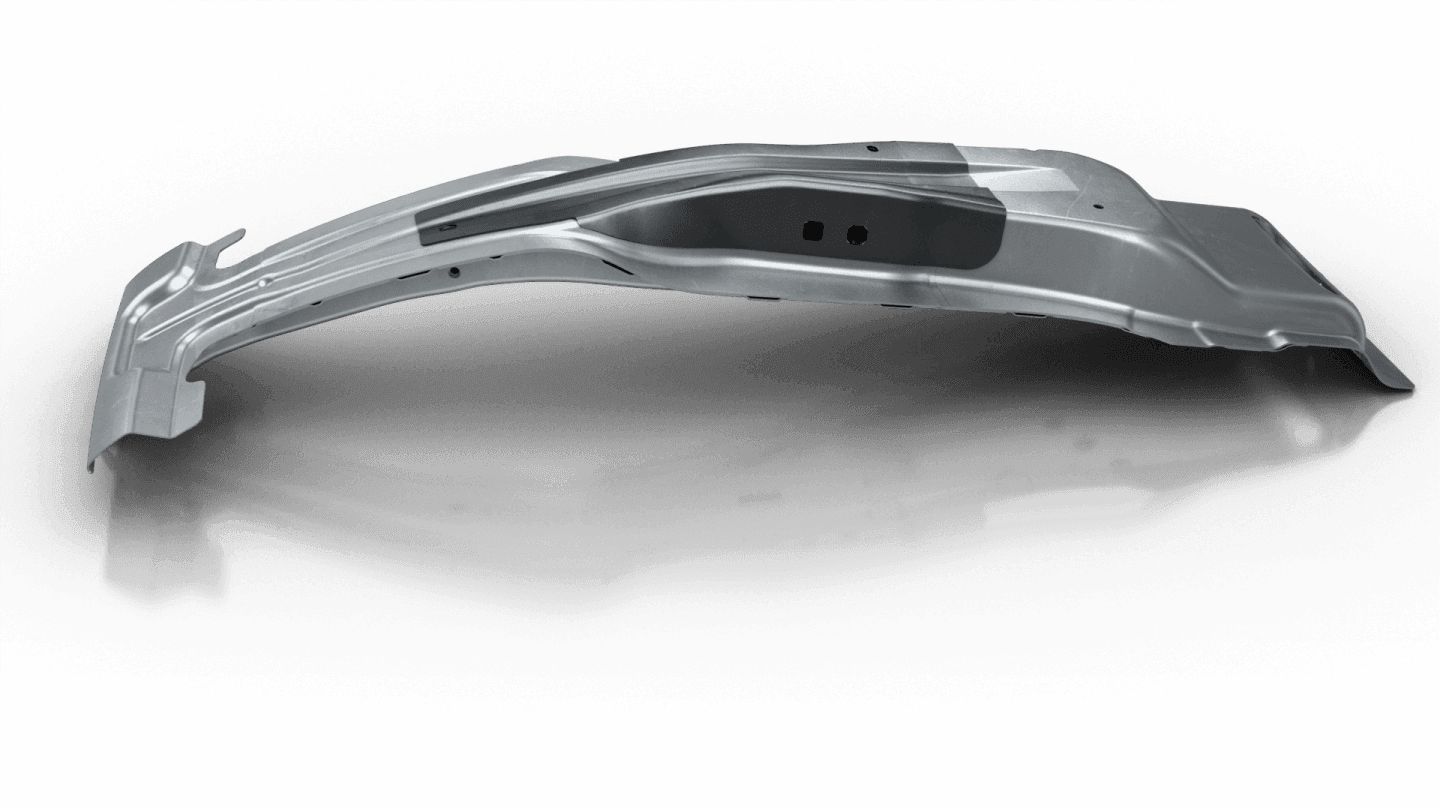

The hot-dip galvanized steel strut dome is used to attach the coil springs and shock absorbers on both sides of the vehicle. They are welded to the body above the wheel arches.

Manufacturing Processes:

- Blank Stamping

- Drawing

- Final Cold Forming & Trimming

The battery box is located under the passenger cabin of electric vehicles and serves as a housing for the battery cells.

Manufacturing Processes:

- Blank Stamping

- Cold Forming

- Laser Welding

- Projection Welding

- Resistance Spot Welding

- Stud Welding

- Blind Riveting

- Painting

- Sealing Foam Application

- Final Assembly

- Leak Test