The B-pillar is the critical crash-relevant connection between the vehicle floor and roof in the middle of the passenger compartment. It absorbs the forces in the event of a side impact and stabilizes the passenger cell against vertical deformation so that the vehicle occupants remain unharmed. To ensure maximum safety, all GEDIA pillar reinforcements are made from high-strength and ultra-high strength steel grades.

Manufacturing Processes:

- Blank stamping

- Hot Forming

- Laser Cutting

- Adhesive Application

- Resistance Spot Welding

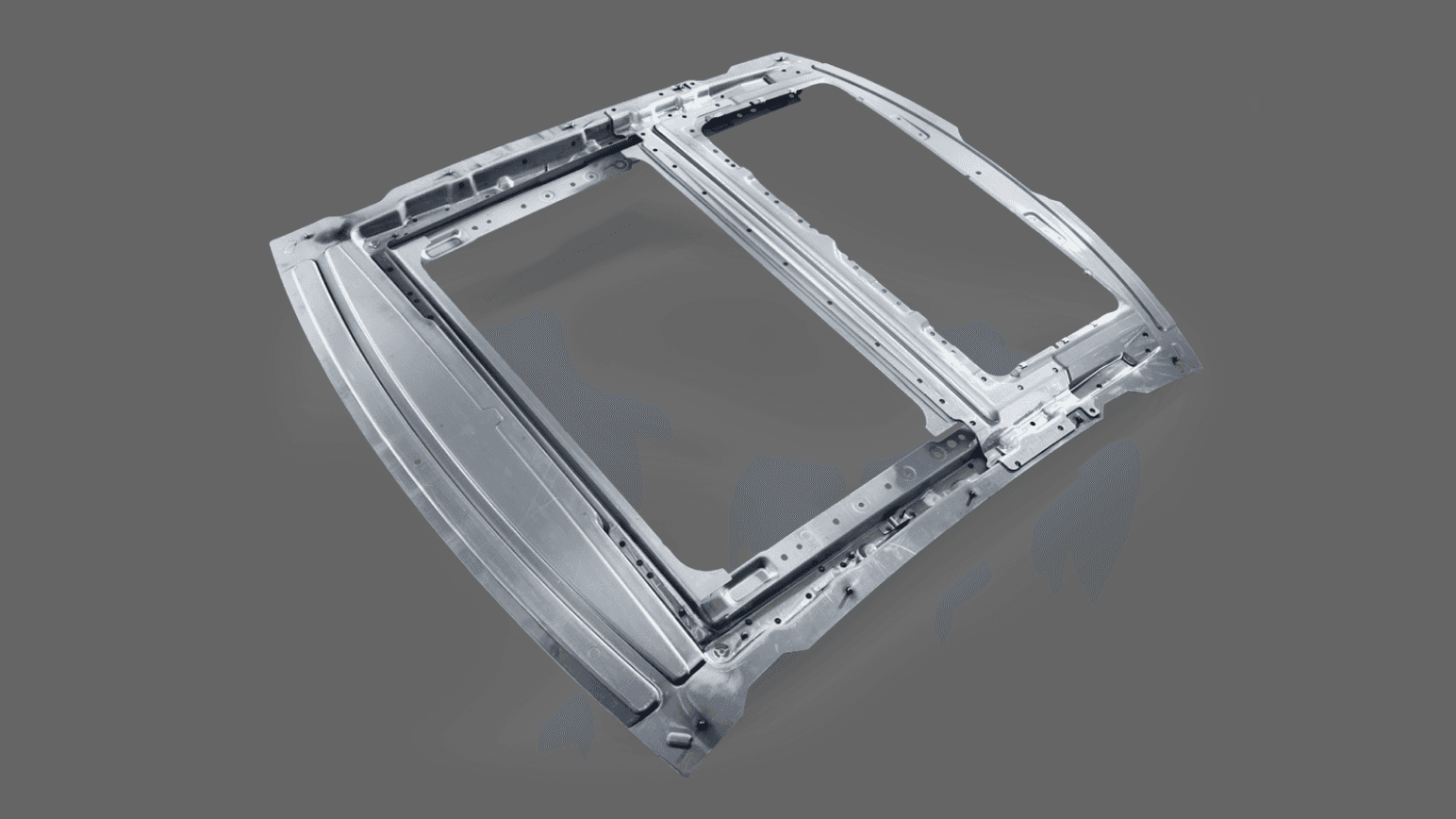

The roof module accommodates the entire sliding glass roof system. It is assembled with the system and finally installed in the painted body.

Manufacturing Processes:

- Cold Forming

- Adhesive Application

- Resistance Spot Welding

- Stud Welding

- Painting

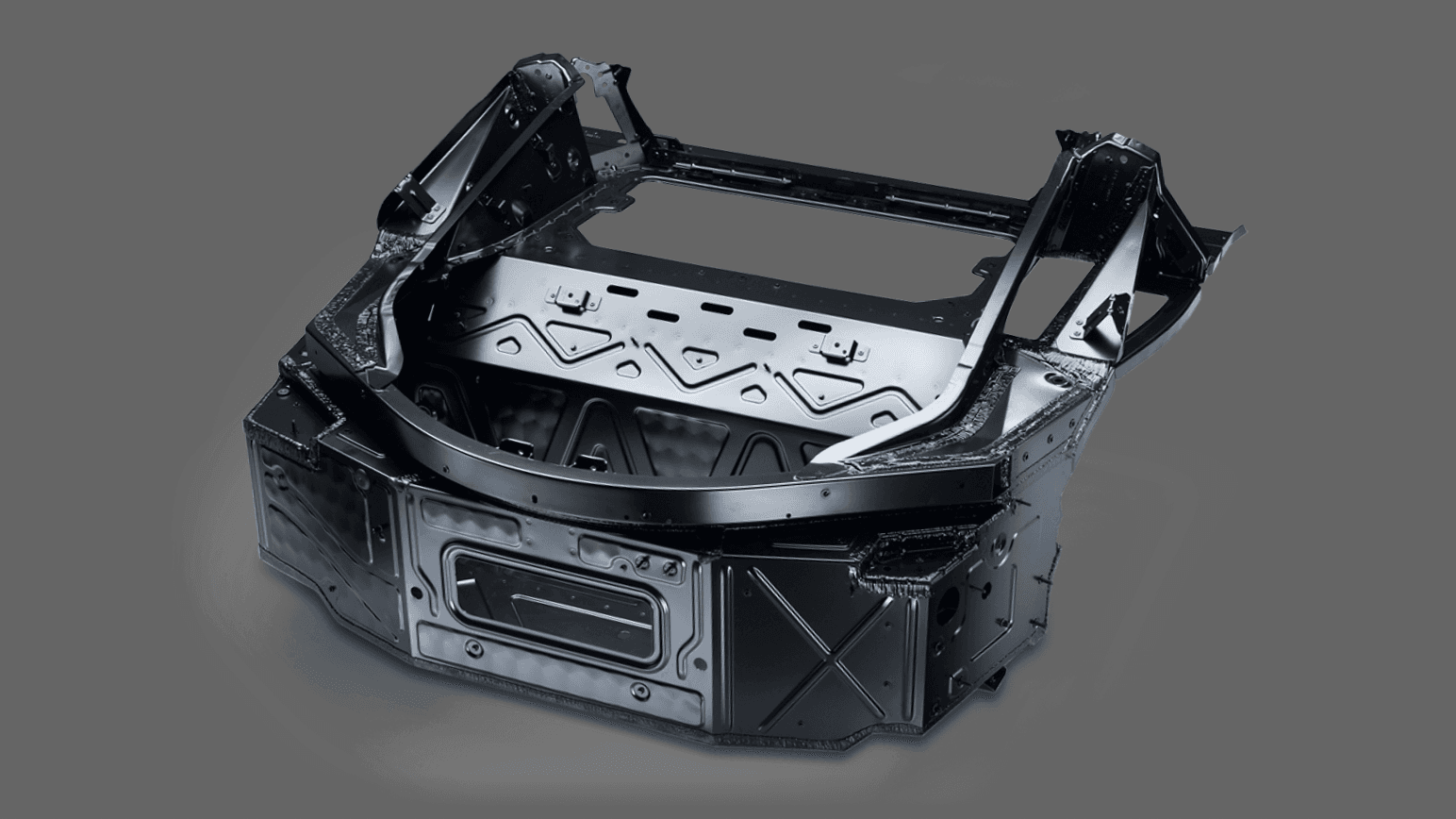

The rear structure assembly extends from the rear bumper to the rear seats. It consists of four extruded profiles, 34 sheet metal components, 439 self-pierce rivets, seven meters (approximately 23 feet) of adhesive seam, 86 blind rivet bolts and nuts, and eight meters (approximately 26 feet) of special seam sealing.

Manufacturing Processes:

- Profile Extrusion

- Cold Forming

- Stretch Bending

- Adhesive Application

- Self-Pierce Riveting

- MIG Welding

- Painting

- Sealer Application

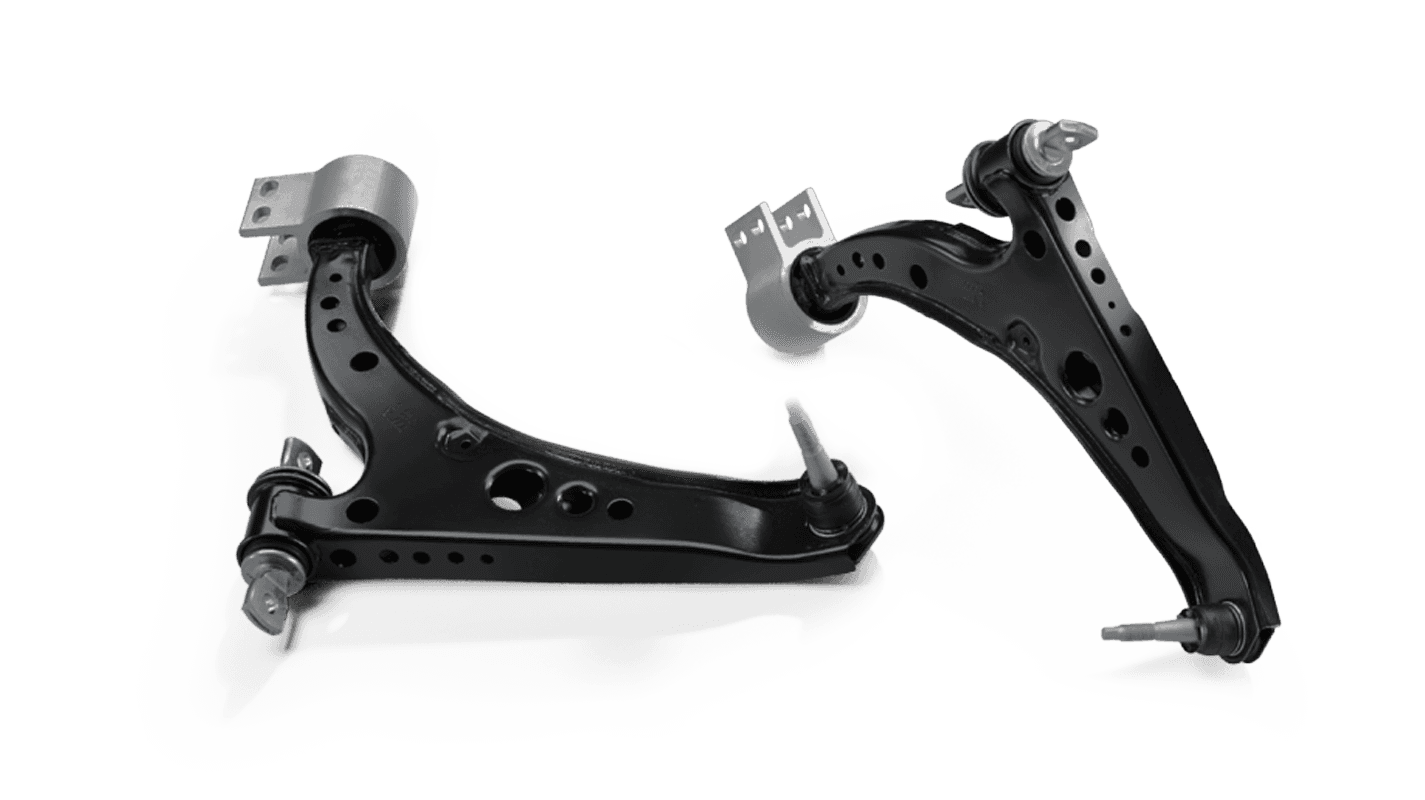

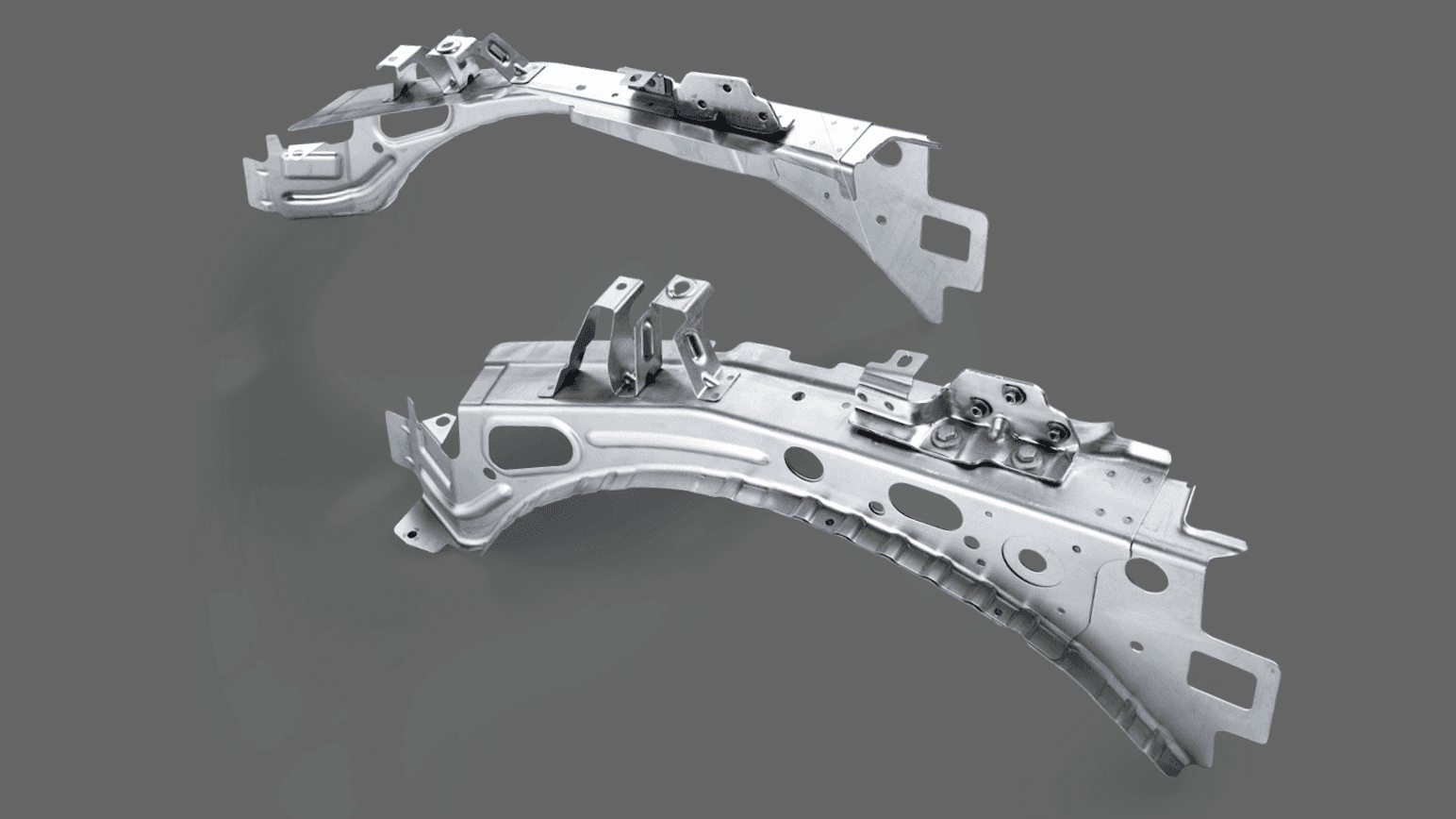

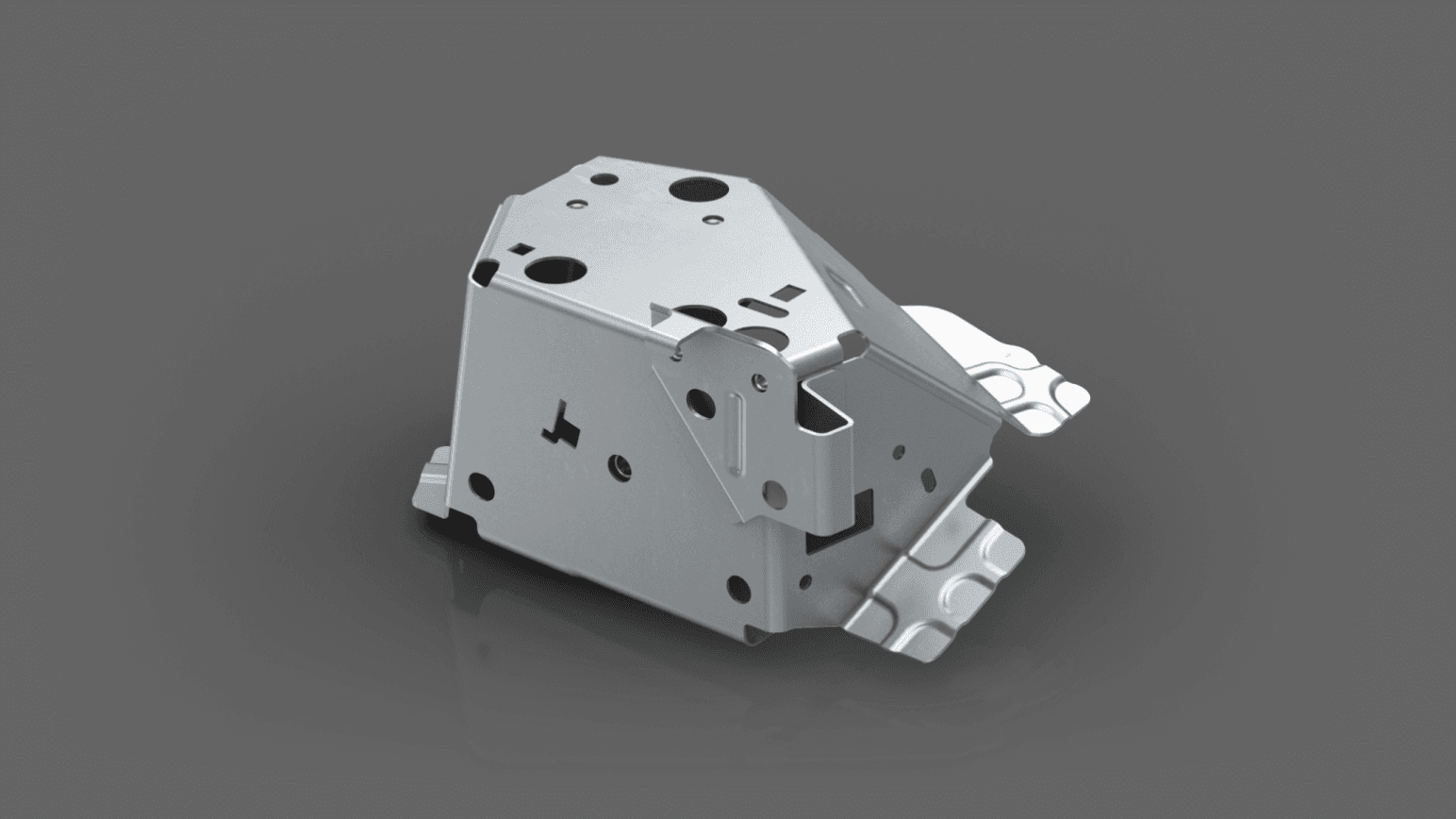

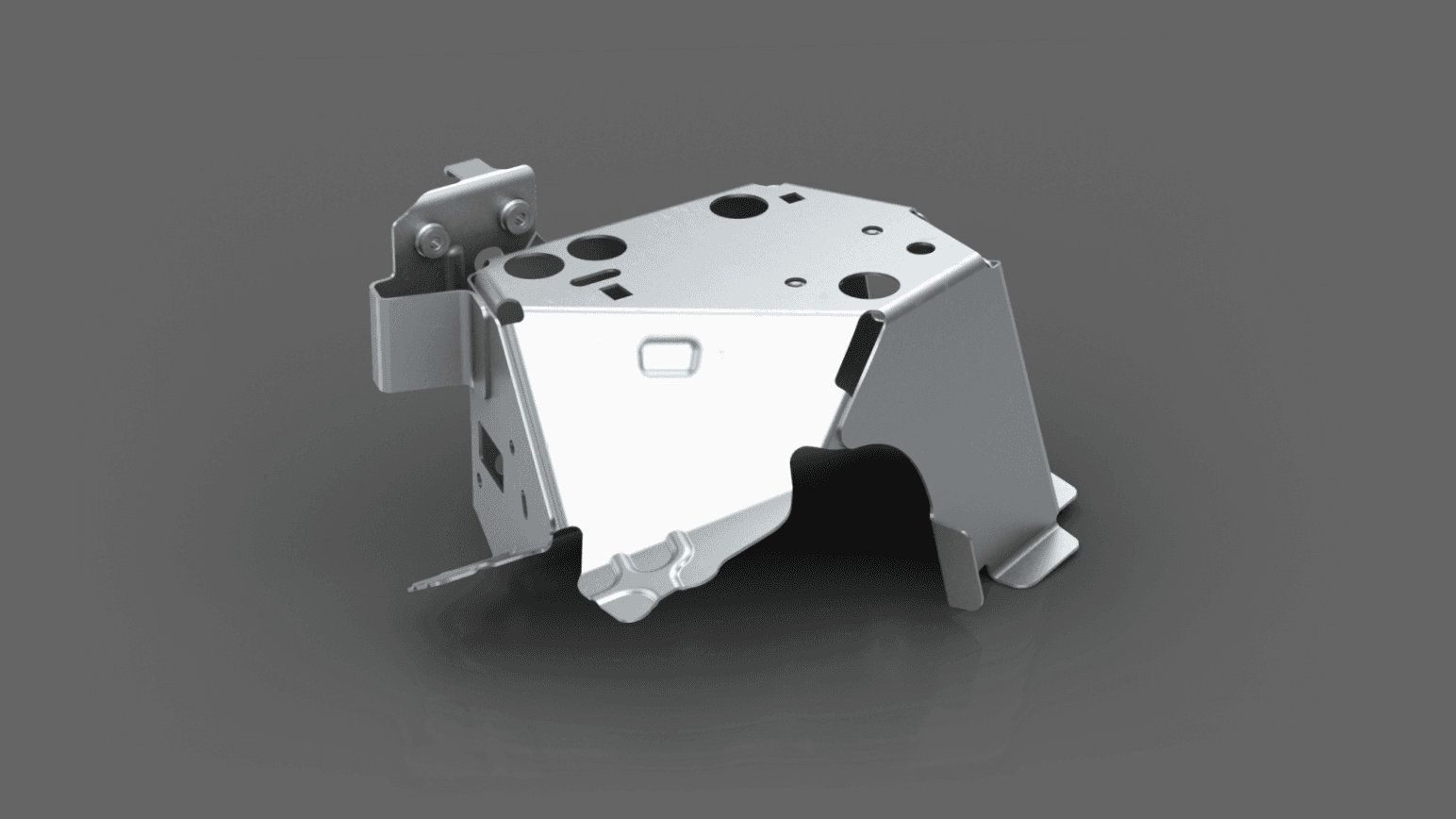

The wheel arch mount is used for various front end fastening and crash functions. It holds the wheel arch, the hood hinges, and the hood crash elements.

Manufacturing Processes:

- Cold Forming

- Projection Welding

- Resistance Spot Welding

- Final Assembly

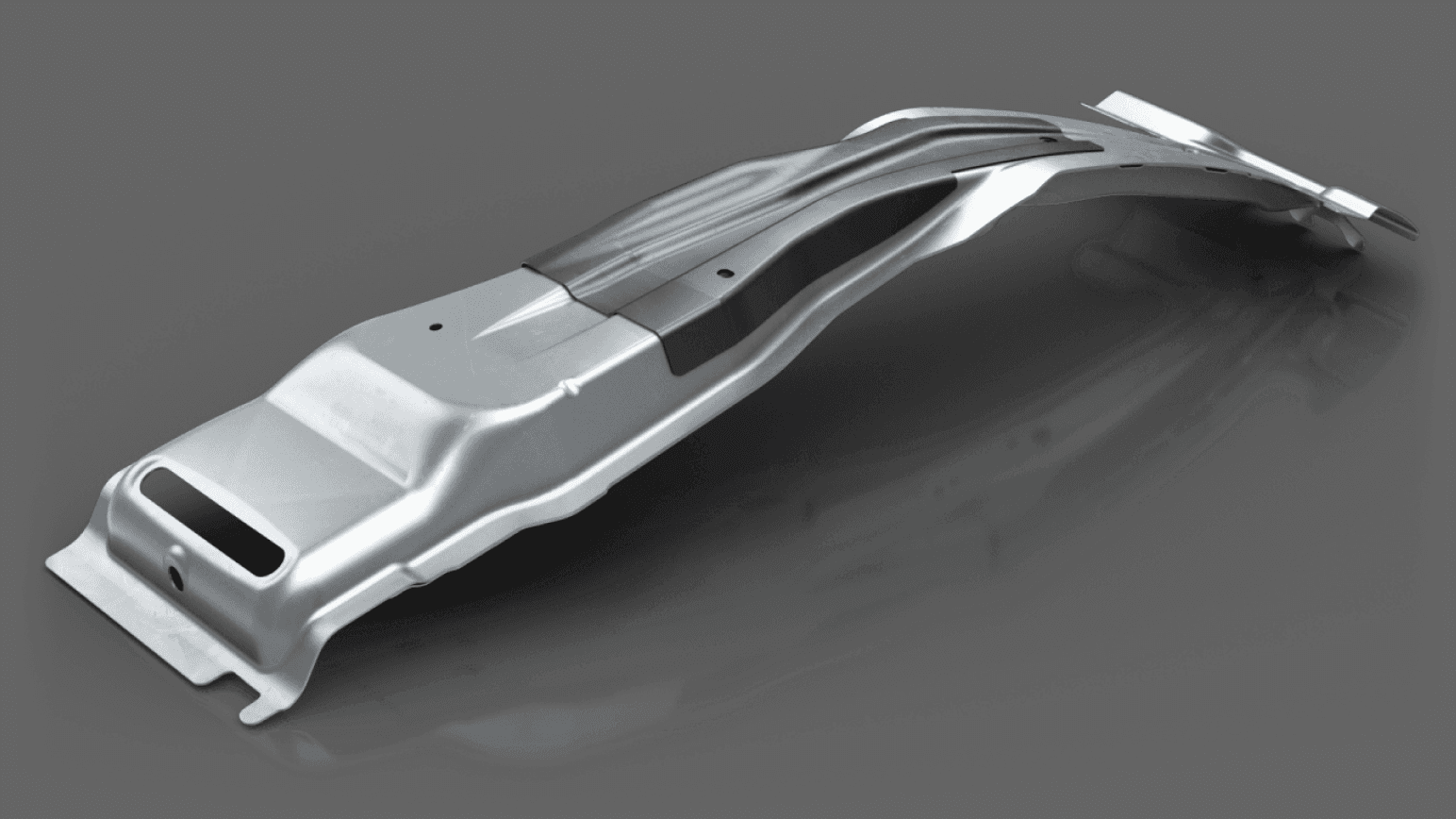

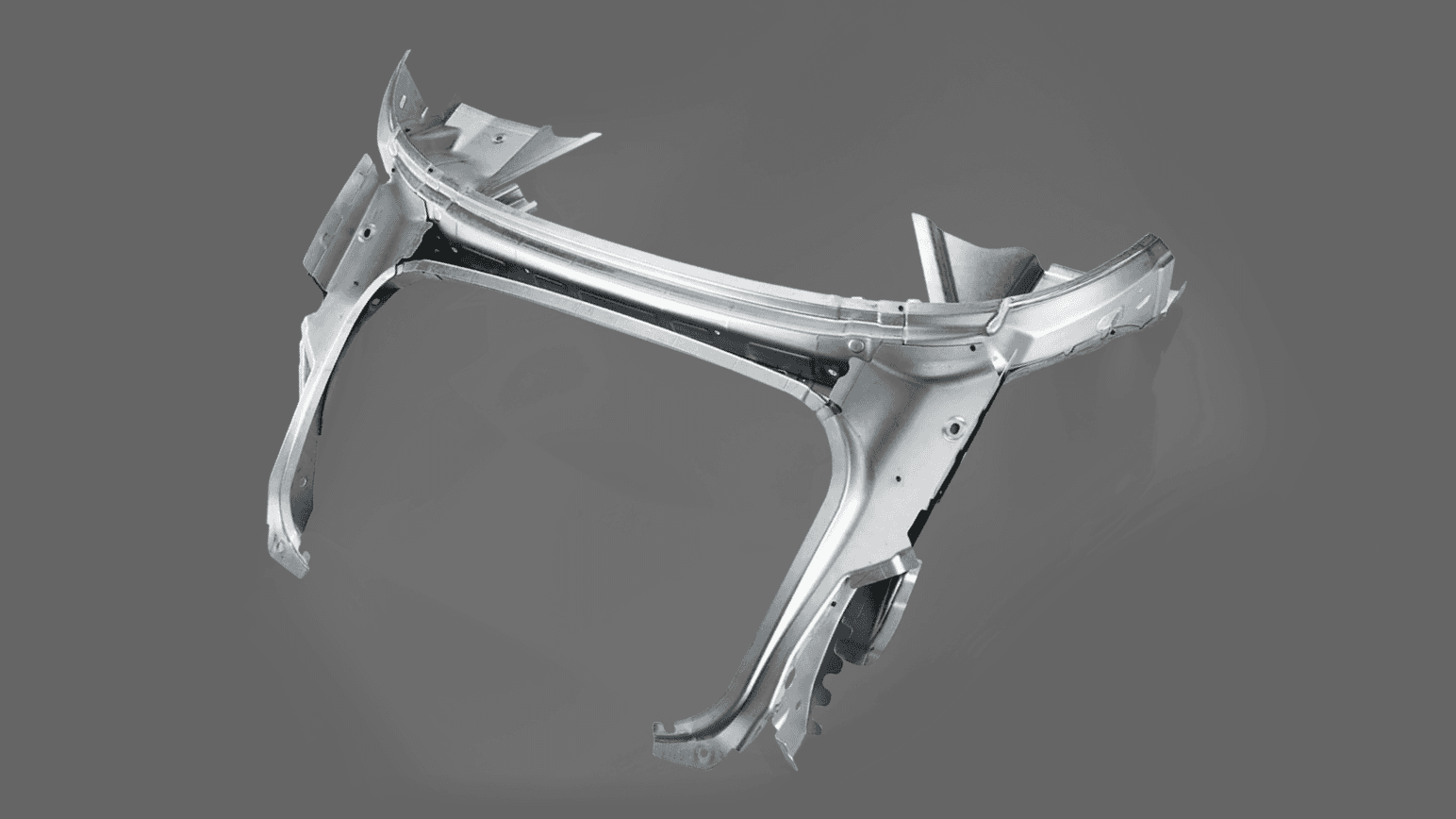

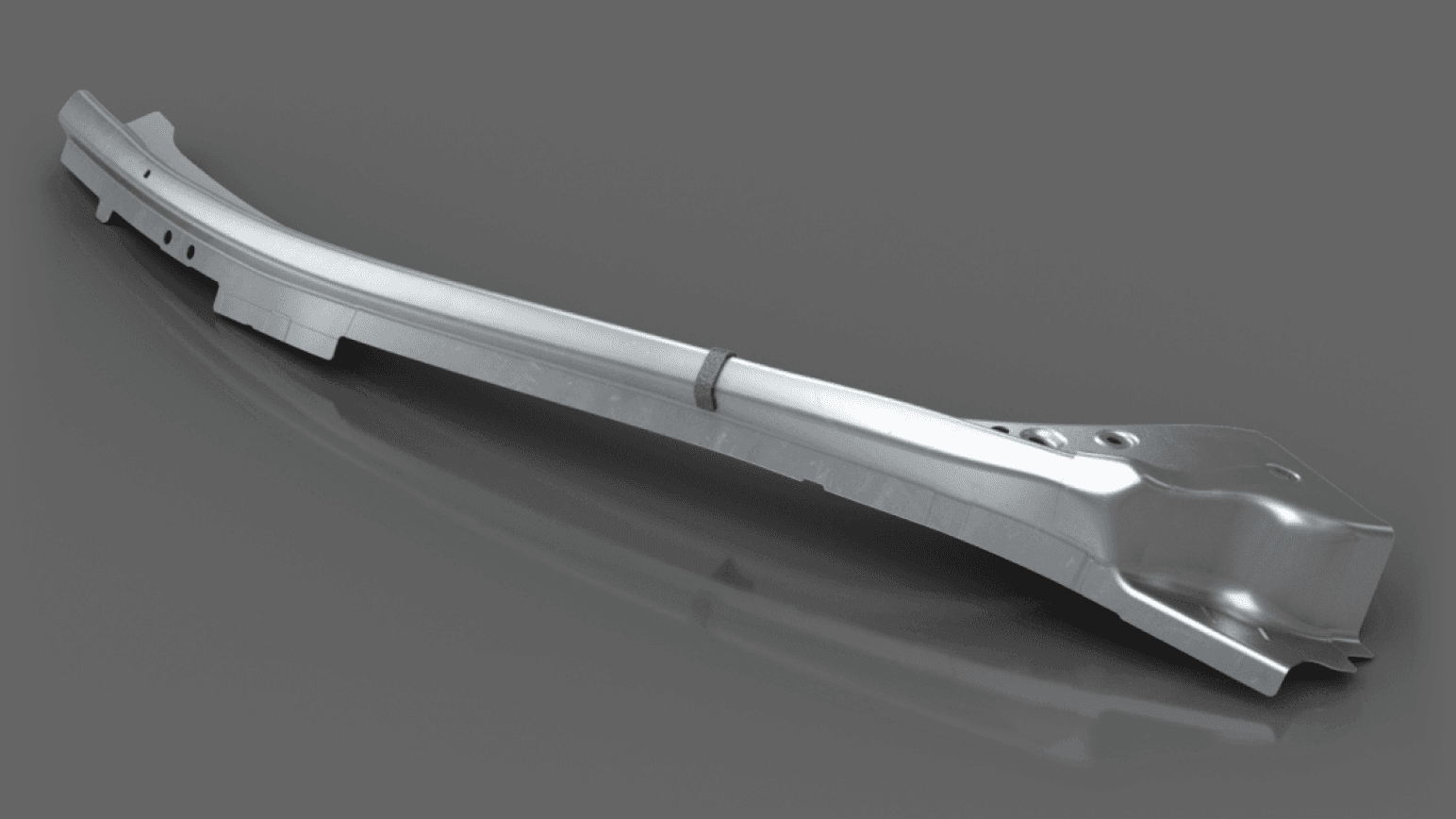

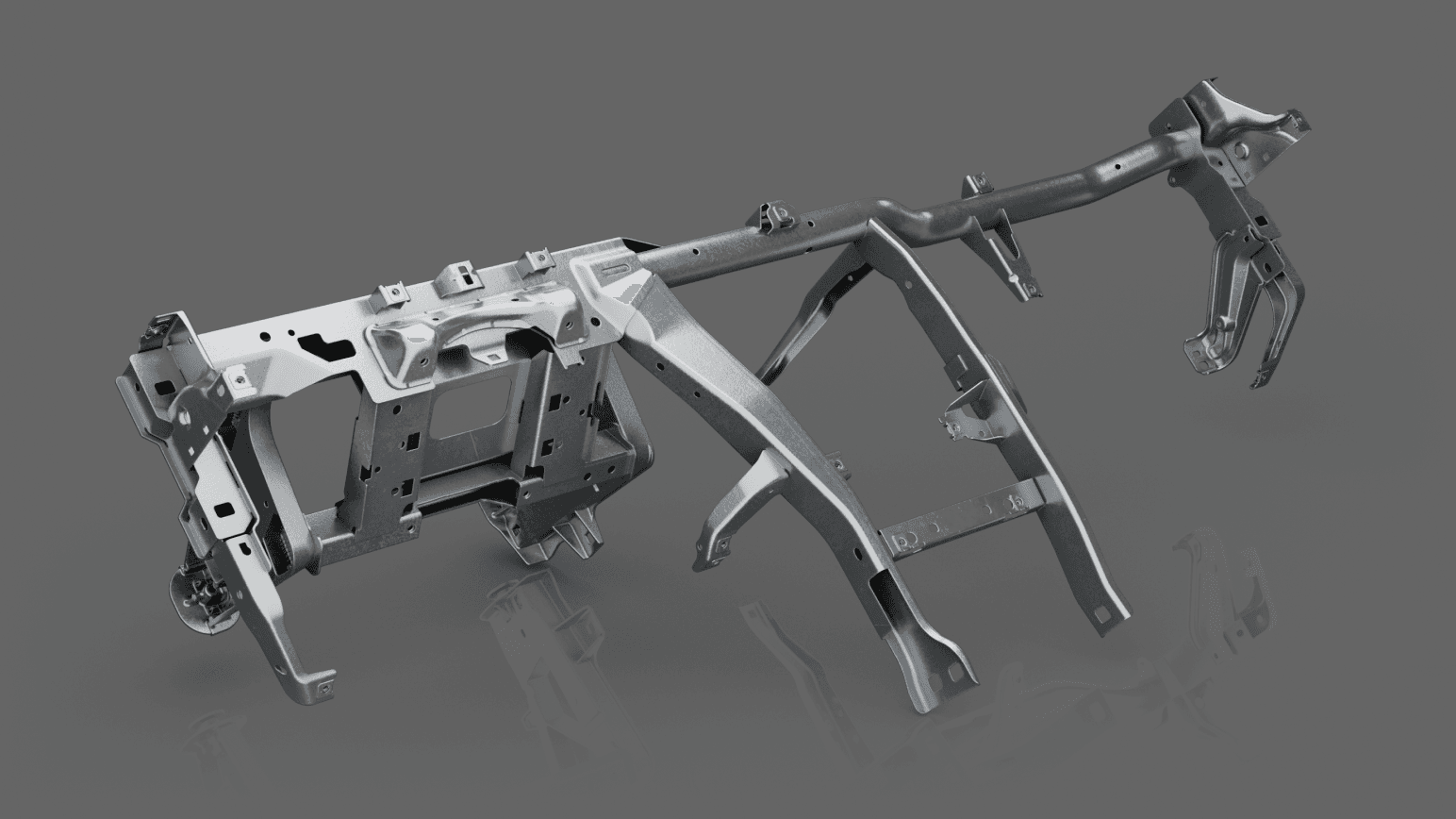

The rear frame is designed to accommodate both the functional elements of the convertible top at the front and the tailgate at the rear.

Manufacturing Processes:

- Cold Forming

- Resistance Spot Welding

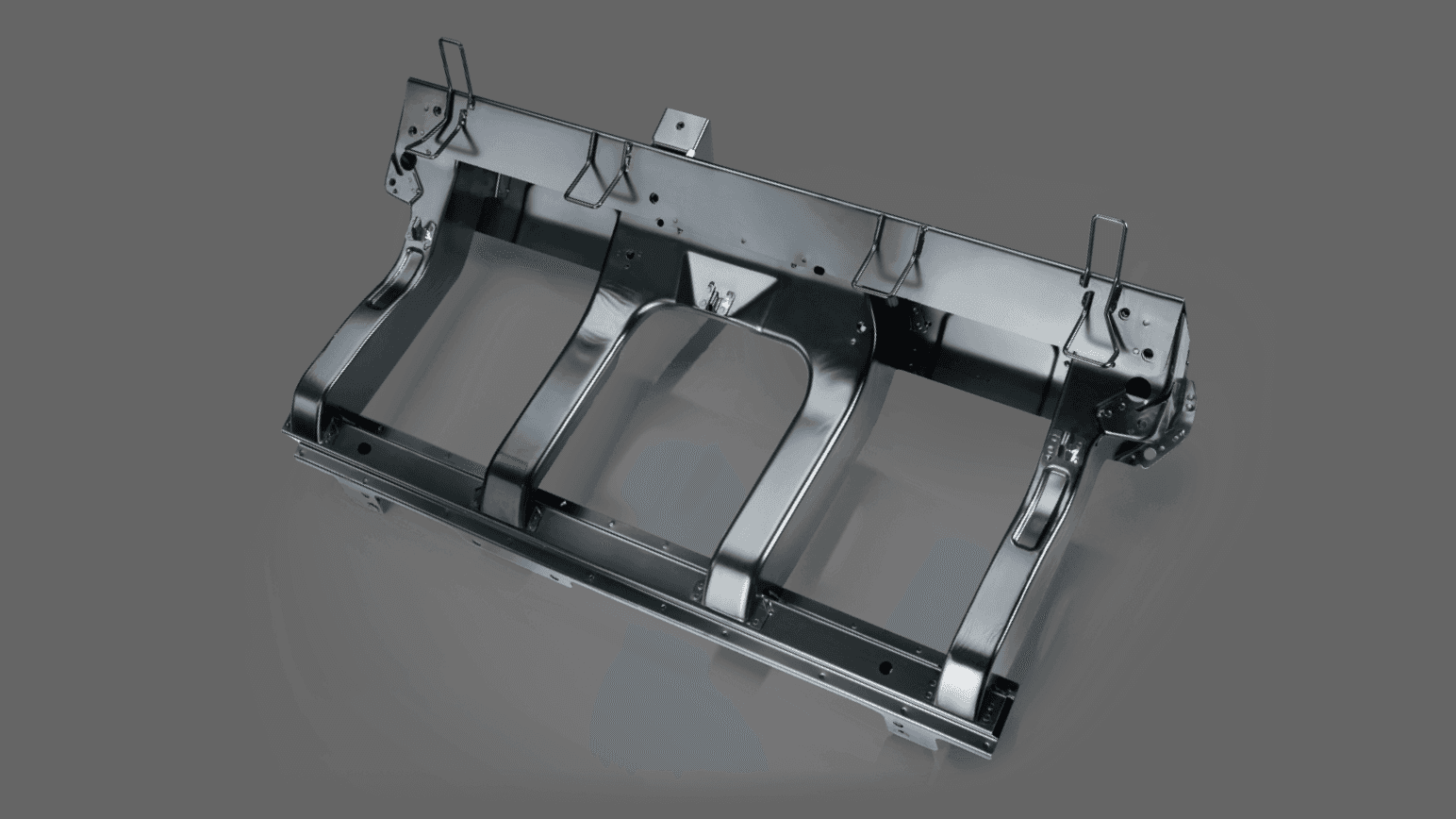

The rear seat mount is a safety-relevant component and is used to secure the rear seat and Isofix fastening system.

Manufacturing Processes:

- Cold Forming

- Projection Welding

- Resistance Spot Welding

- MAG Welding

- Painting

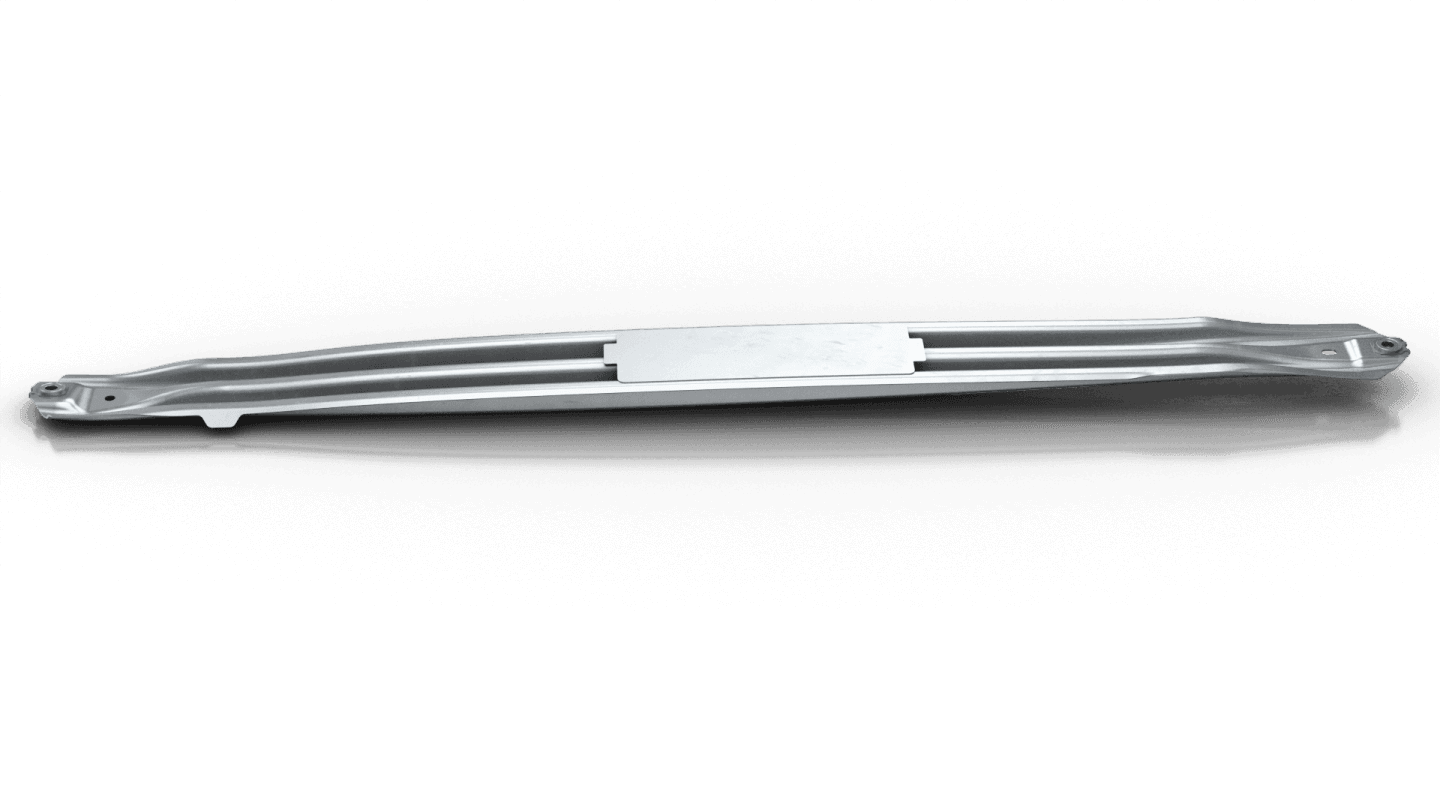

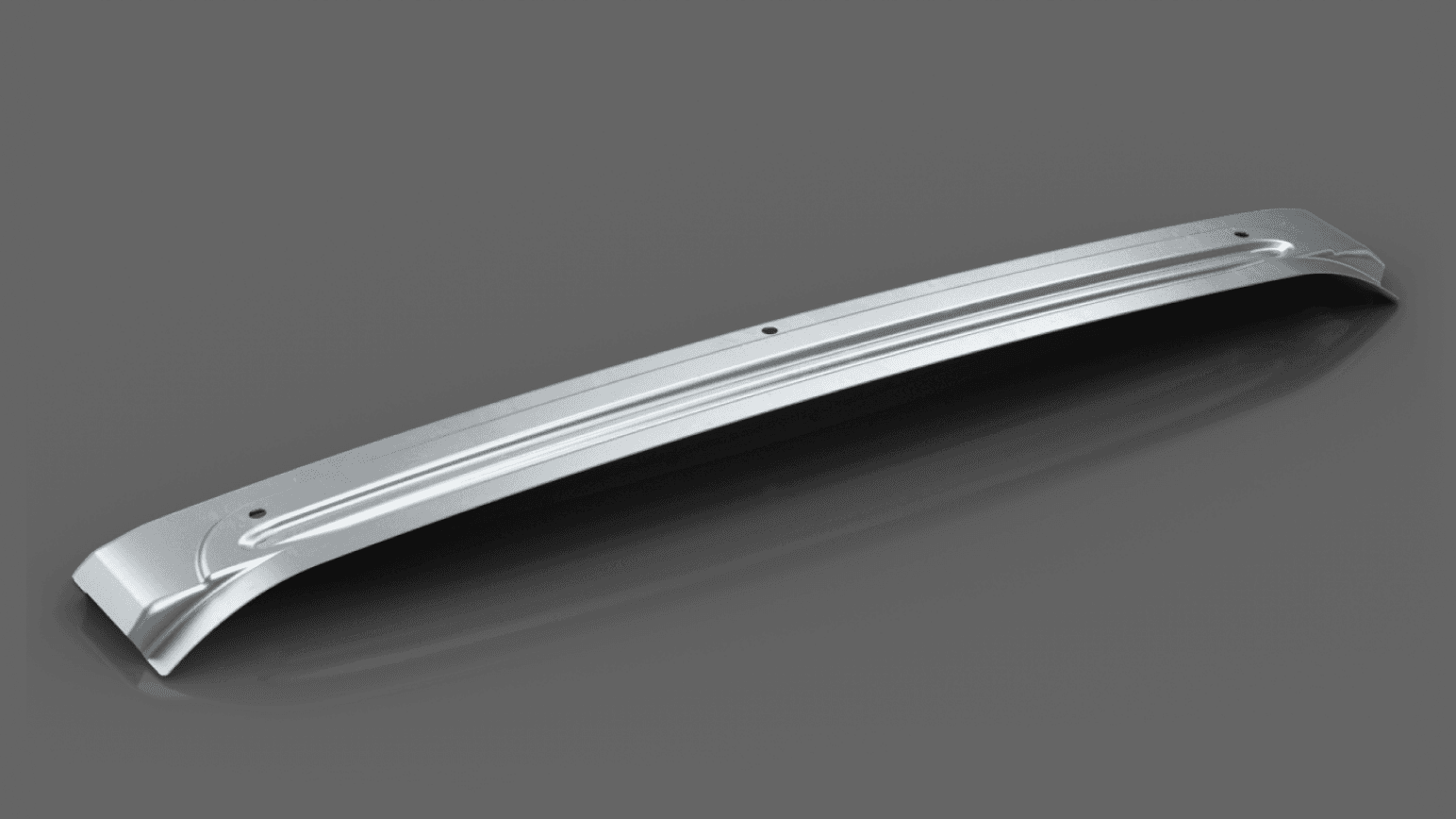

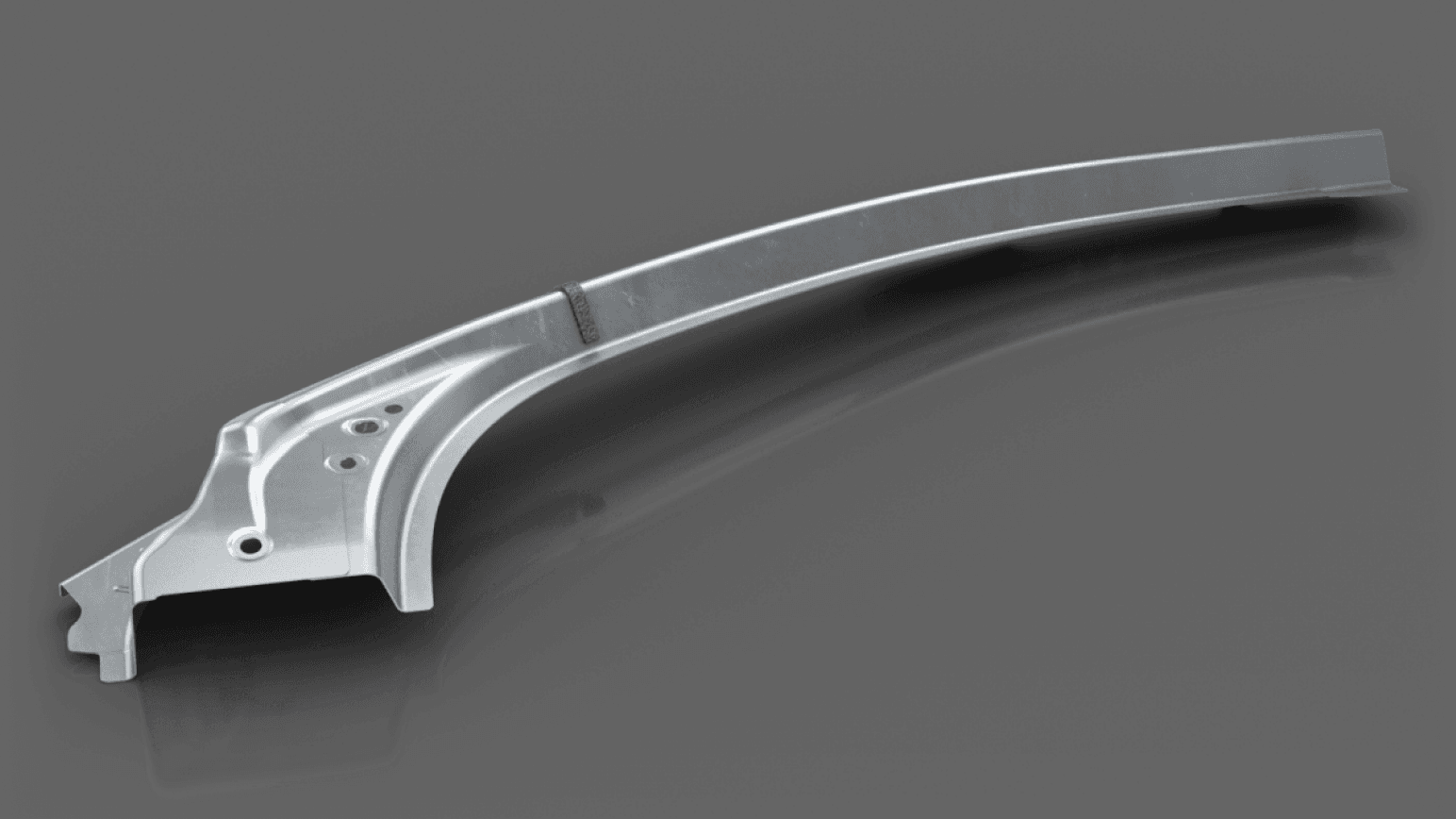

The roof crossmember stiffens the roof and stabilizes the passenger compartment. It is made of aluminum to ensure the highest standards of economy and functionality.

Manufacturing Processes:

- Blank Stamping

- Cold Forming

- Painting

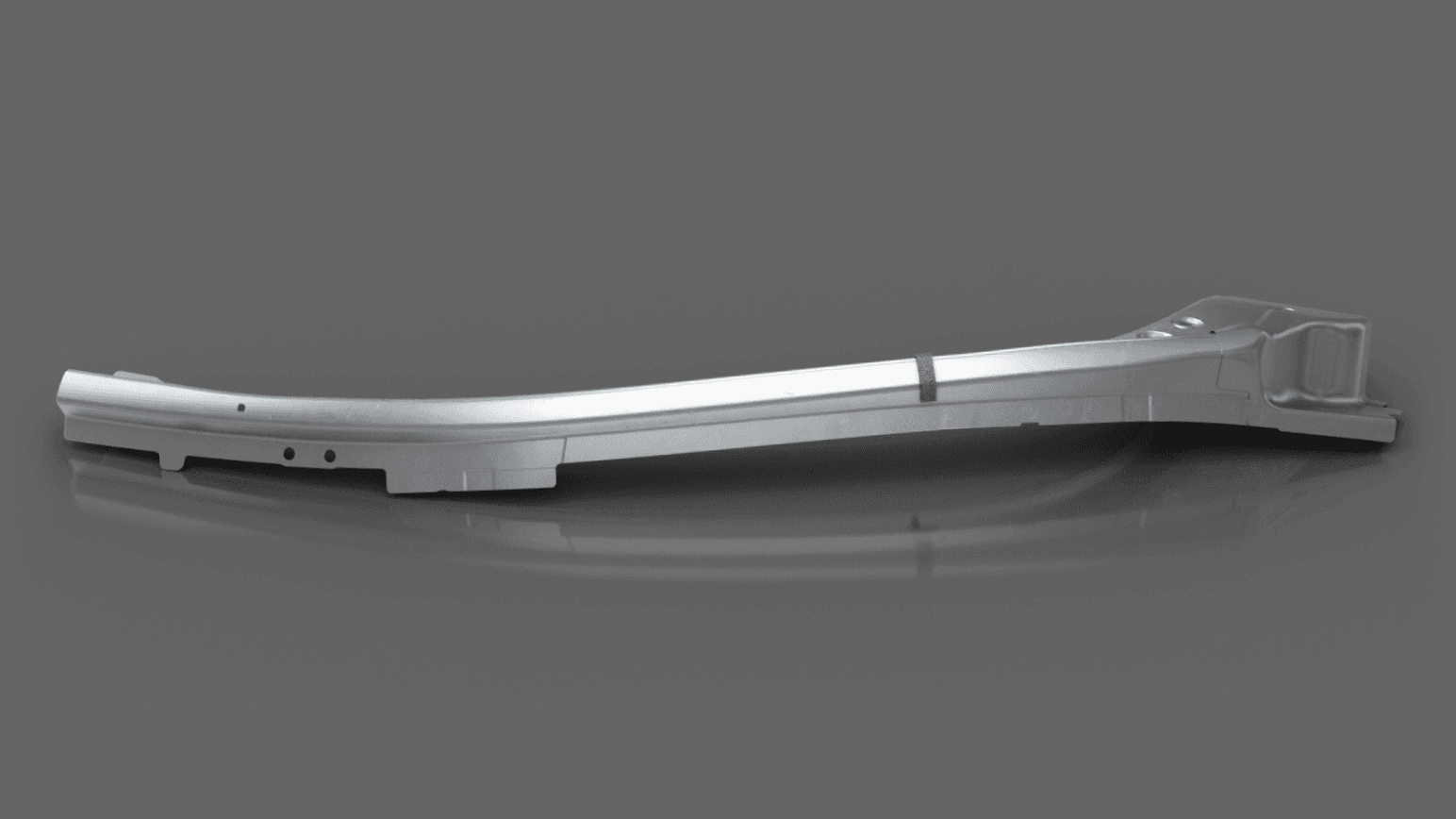

The A-pillars are located at the front of the vehicle and are used to frame the windshield and attach the driver and passenger door hinges. The A-pillars help to ensure the stability of the occupant cabin in the front area.

In a convertible, the a-pillars are reinforced so that the stability of the passenger compartment is maintained in the event of an accident.

Manufacturing Processes:

- Blank Stamping

- Cold Forming

- Hot Forming

- Laser Cutting

- Adhesive Application

- Resistance Spot Welding

The belt box serves as a housing for the seat belt retractor and, thanks to its high stability, ensures occupant safety and comfortable handling of the seat belts.

Manufacturing Processes:

- Cold Forming

- Projection Welding

- Resistance Spot Welding

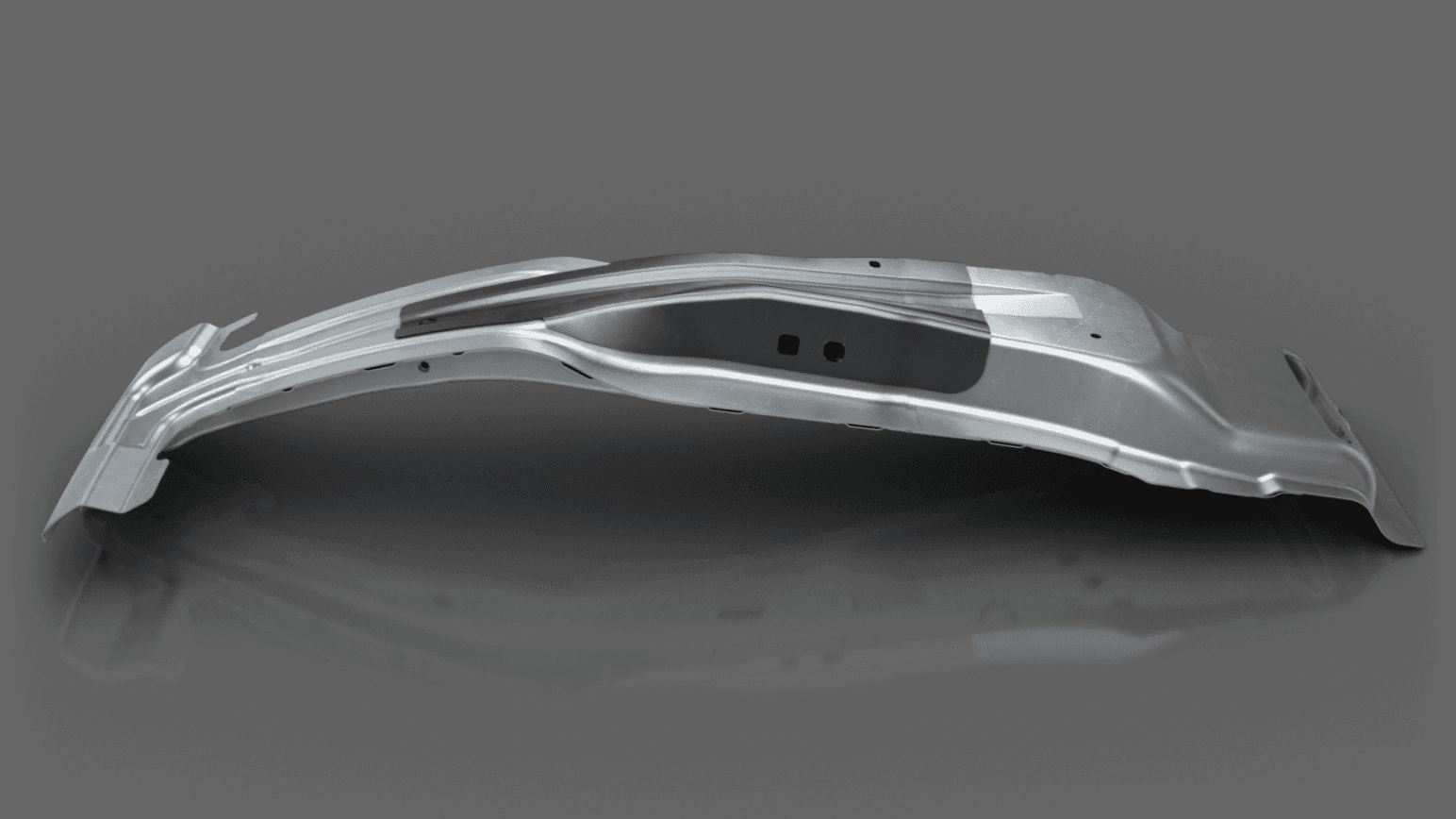

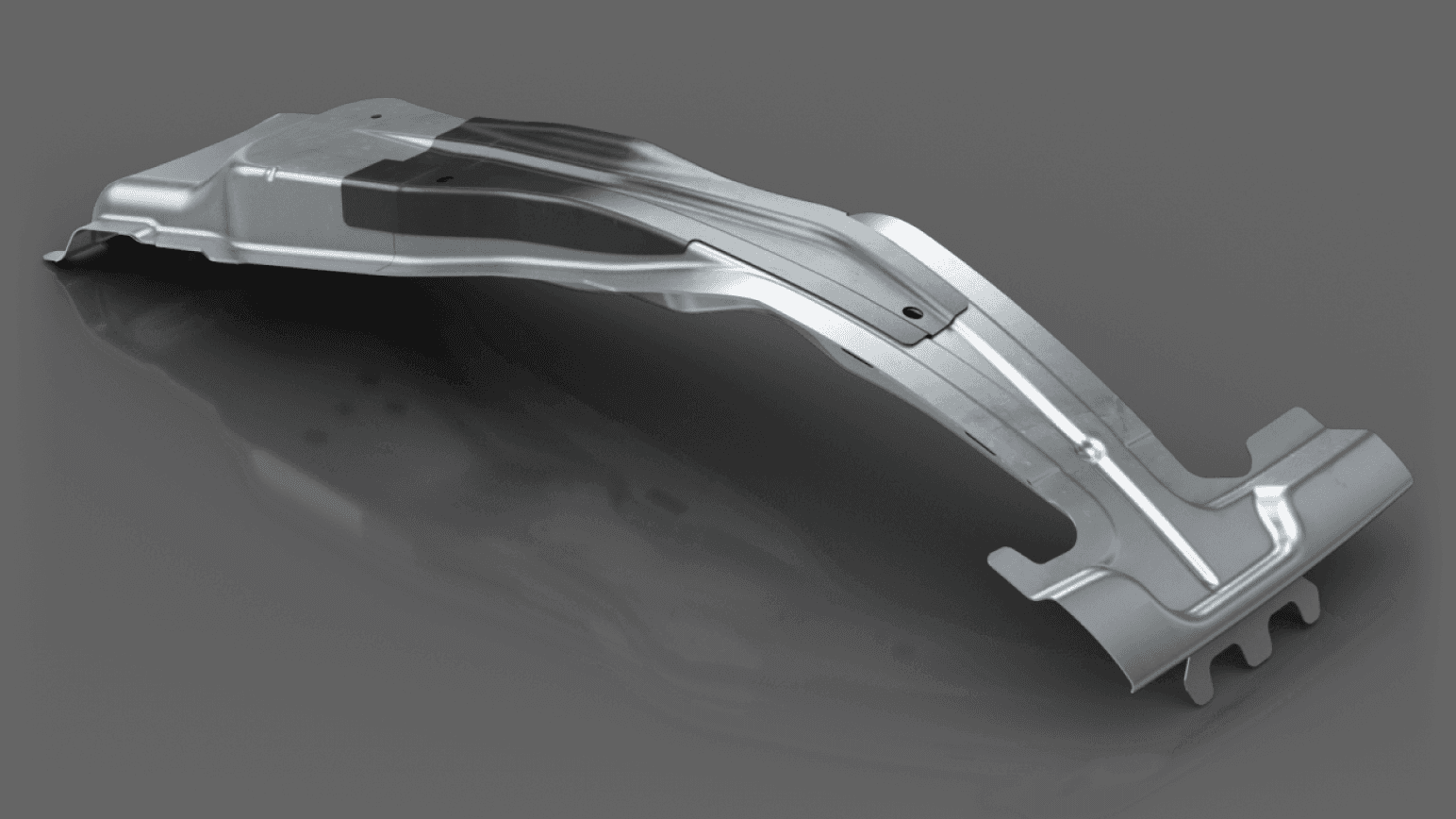

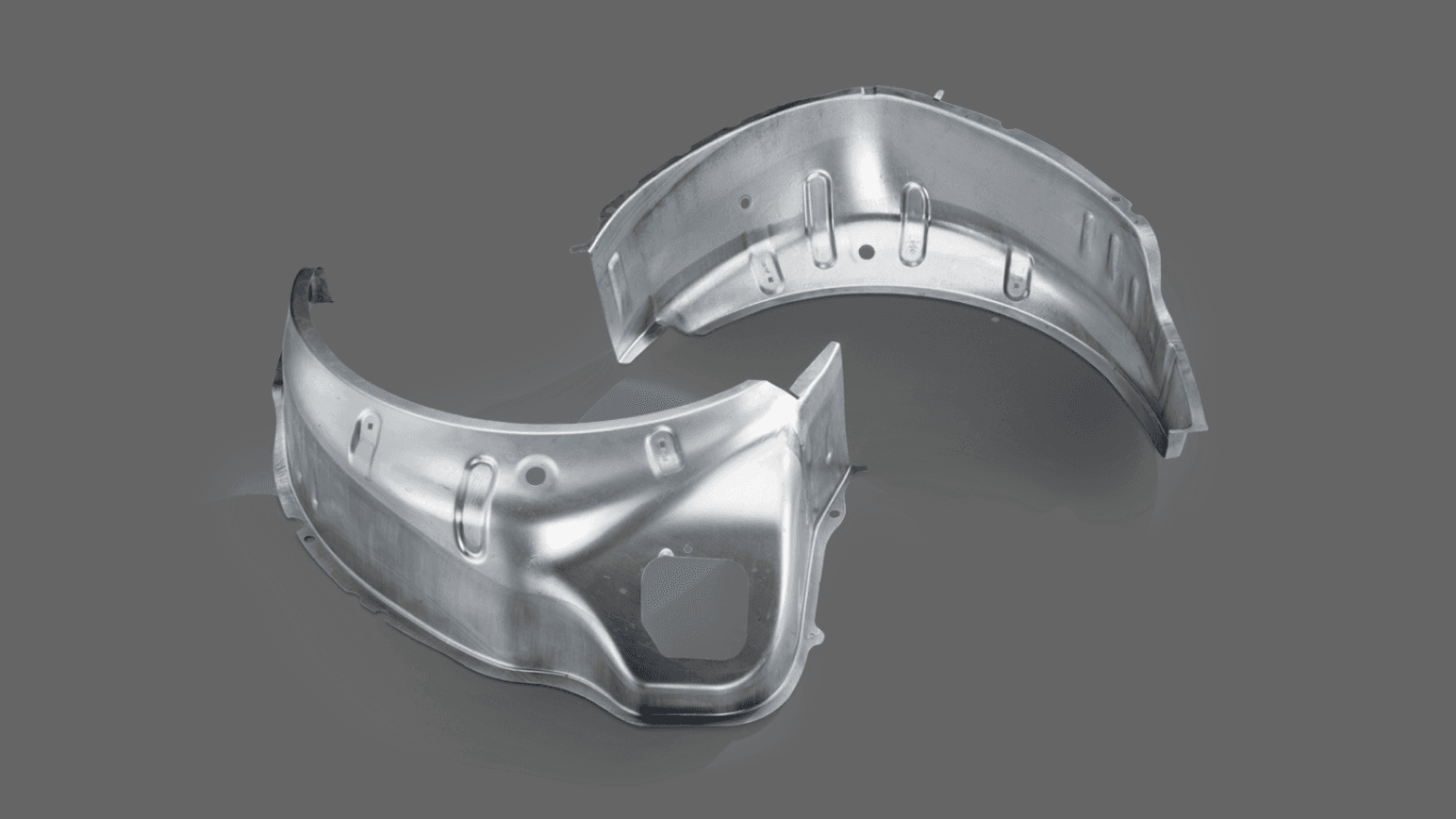

The wheel arch, also known as the wheelhouse, is the recess in the body where the wheels are mounted. They are used to transmit the force of the wheel suspension to the body and also act as a splash guard for the cab, engine compartment and surrounding area. The wheel housing must therefore be corrosion resistant.

Manufacturing Processes:

- Blank Stamping

- Cold Forming

- Calibration

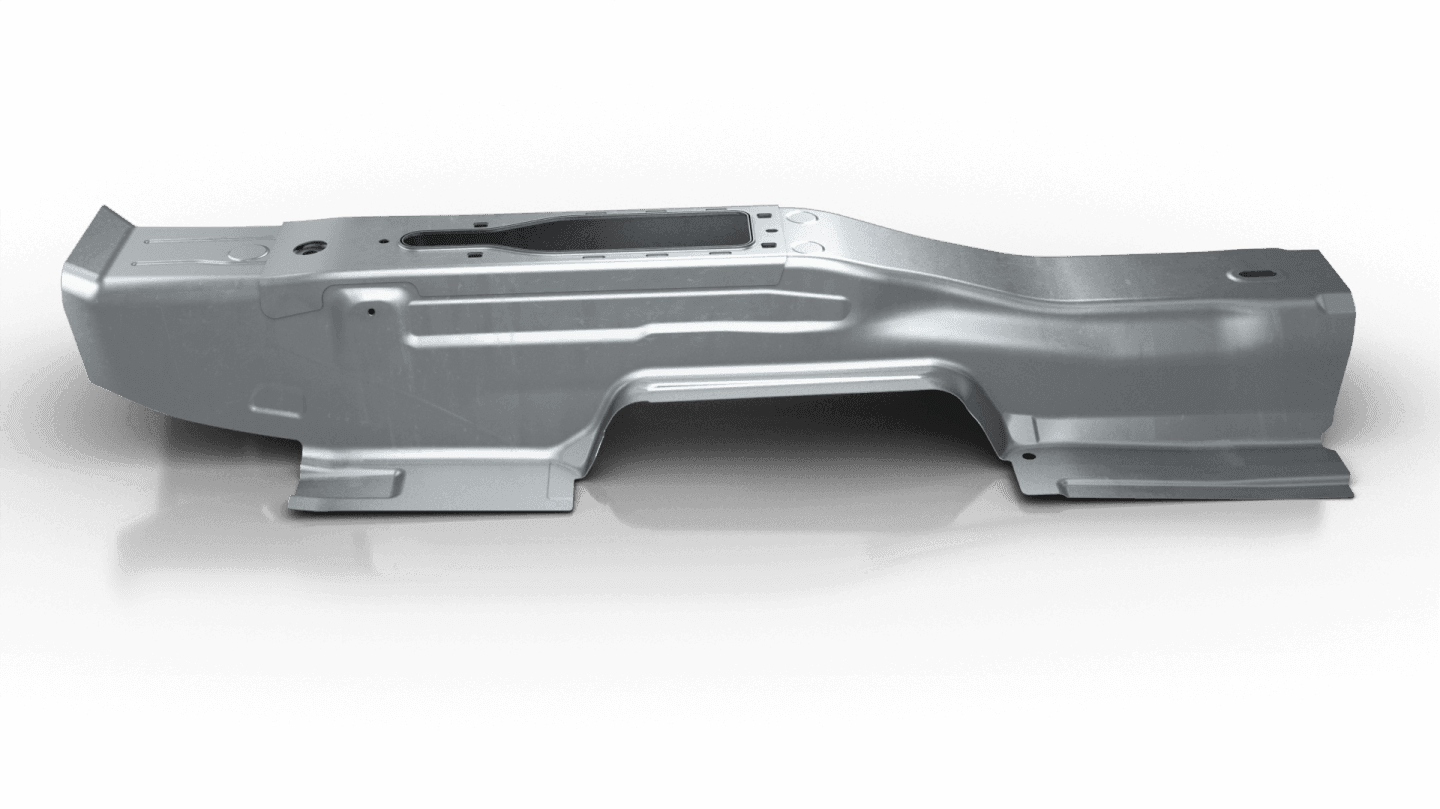

The firewall separates the engine compartment and the passenger compartment, and can thus keep noise, heat and vibrations out of the passenger compartment to increase comfort for the occupants. At the same time, it protects the passenger compartment from hazards such as engine fluids or smoke in the event of a defect. The firewall also contributes to the structural stability of the vehicle and is an important component for safety.

Manufacturing Processes:

- Blanking

- Hot forming

- Hot forming with TemperBox®

- Cold forming

- Nuts and bolts

- Lasering

- Resistance spot welding

- Gluing

- Resistance element welding

- CDP

The cross car beam is mounted in the vehicle perpendicular to the driving direction. Its main function is to safely and stably support various components such as the dashboard, heating, ventilation and electronics. At the same time, it provides additional stability and rigidity to the vehicle body.

Manufacturing Processes:

- Punching

- Projection Welding

- CMT MAG Welding Process